Wastewater Treatment Facility Safety Guidelines – Quick Tips

Wastewater treatment facilities are dangerous workplaces. Slips, trips and falls; permit-required confined spaces; mechanical equipment; pathogenic bacteria; and hazardous chemicals are just a few of the hazards faced. Identifying these hazards, assessing the risks and following the hierarchy of controls to either eliminate or reduce exposure to these hazards is a must.

Slips, Trips and Falls

The potential for slips, trips and falls exists in every wastewater treatment facility. Steps needed to ensure your safety include identifying areas that are prone to excessive water and puddling, fixing leaks promptly, practicing good housekeeping, using non-slip surfaces and wearing slip-resistant footwear.

Permit-Required Confined Spaces

In wastewater treatment confined-space hazard awareness can mean the difference between life and death. Aeration basins, digesters, storage tanks, sample vaults, and manholes are all potential permit-required confined spaces.

The Occupational Safety and Health Administration (OSHA) defines a confined space as an area that:

- Is large enough and so configured that an employee’s body can enter and perform assigned work;

- Has limited or restricted means for entry or exit; and

- Is not designed for continuous employee occupancy.

A permit-required confined space is defined as a confined space that:

- Contains or has a potential to contain a hazardous atmosphere;

- Contains a material that potentially could engulf an entrant;

- Has an internal configuration that could trap or asphyxiate an entrant through inwardly converging walls or a floor that slopes downward and tapers to a smaller cross-section; and/or

- Contains any other recognized serious safety or health hazards.

There are several steps that you should follow when developing a confined space program. The first is to evaluate the workplace and determine whether it contains permit-required confined spaces. If it is determined that there are permit-required confined spaces, then employees must be informed of the dangers by posting signs or some other equally effective means.

The next decision that must be made is whether or not the confined space should be entered:

- If NO — Effective measures to prevent employees from entering the permit space must be taken.

- If YES — A written permit space entry program must be developed and implemented.

Please refer to Quick Tips #115: Confined Spaces, 29 CFR 1910.146, which provides additional details on confined spaces and has a permit-required, confined-space decision flow reference chart.

Lockout/Tagout

Routine maintenance, inspections, repairs and testing take on another important area of safety known as lockout/tagout. Nearly 90 percent of the activities that require lockout/tagout are applications that require de-energizing an electrical source that provides power to a system or equipment components within the system. These might include pumps, electrical motors, valves and mixing systems. The remaining activities include lockout/tagout of pipelines and systems, and valves in which the energized source of potential danger could be water under pressure, air pressure and/or steam. All of these hazardous energy sources are present in wastewater treatment facilities.

Pathogenic Bacteria and Hazardous Chemicals

Wastewater contains bacteria, funguses, parasites and viruses that can cause intestinal, lung and other infections. Operators who are not protected from exposure can get sick.

All employees must understand the importance of making good personal hygiene a habit. Frequent hand washing with an anti-bacterial soap is a good place to start. Any open cuts or skin abrasions must be properly covered and protected. Providing a location for employees to change after their shift is highly recommended – work clothes should not be worn home.

Chlorine (gas), sodium hypochlorite, lime, aluminum sulfate, ferric chloride, various polymers, and a variety of acids and bases are commonly used to treat wastewater. Being aware of the chemicals, the physical state (liquid, solid or gas) and the physiological effects that are caused by exposure is paramount. Proper and safe chemical management should be part of your wastewater treatment facility’s culture and is everyone’s responsibility.

Chemicals and biological hazards abound in wastewater treatment. Safety data sheets (SDS) help you understand the properties, exposure limits, suggested personal protective equipment (PPE), and emergency actions for the treatment chemicals in use and must be maintained.

Hierarchy of Controls

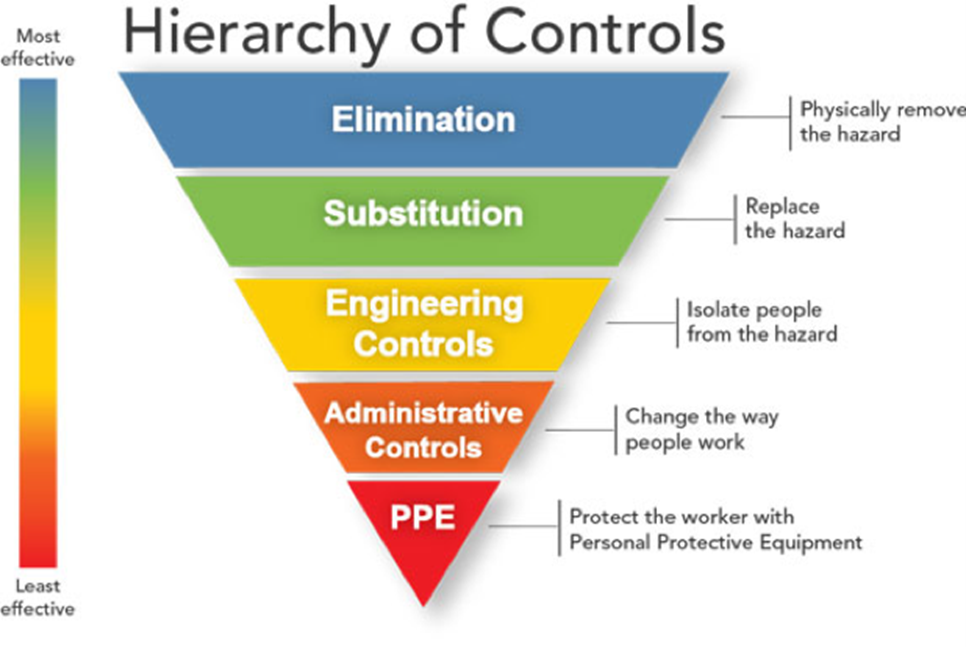

Controlling exposures to occupational hazards is the fundamental method of protecting workers. Traditionally, a hierarchy of controls has been used as a means of determining how to implement feasible and effective control solutions.

One representation of this hierarchy is shown below:

The idea behind this hierarchy is that the control methods at the top are more effective and protective than those at the bottom and should be implemented first if possible. Following the hierarchy of controls normally leads to the implementation of inherently safer systems, where the risk of illness or injury is substantially reduced.

Personal Protective Equipment (PPE)

As a last line of defense employees may depend on PPE to protect themselves from the hazards encountered in wastewater treatment facilities. PPE includes head, eye and face, hearing, respiratory, body, hand, and foot protection as well as fall protection equipment. Please visit Grainger’s Safety Resource Center for PPE to view a variety of related products, services and resources, To determine what PPE employees may need employers are required to perform a PPE hazard assessment of each work area. The purpose of the assessment is to identify any hazards that may be present and what PPE may be appropriate.

Conclusion

Wastewater treatment operations fall under many regulations. Developing written wastewater treatment facility safety guidelines that are specific to the worksite is critical. Regardless of the many safety issues that pertain to wastewater treatment workplaces, enforcing the safety procedures and processes are critical to promoting employee safety.

Commonly Asked Questions

Within the hierarchy of controls, why are engineering controls preferred over administrative and PPE controls?

Engineering controls are preferred over administrative and PPE controls because they are designed to remove the hazard at the source, before it comes in contact with the worker.

Are there specific regulations governing chemical handling and safety at wastewater treatment facilities?

Depending on which chemicals you have at your facility and the amount you store, the following regulations may apply:

- Hazard Communication (29 CFR 1910.1200) – designed to ensure that information about chemical hazards and associated protective measures is shared with and understood by those who may be exposed

- Process Safety Management of Highly Hazardous Chemicals (29 CFR 1910.119) – targets highly hazardous chemicals that could cause catastrophic events and encompasses every aspect of chemical use—system design, written information available, operation, employee training, contractors, pre-startup safety, mechanical integrity, non-routine work, and managing change

- Risk Management Plan (40 CFR Part 68) – Environmental Protection Agency (EPA) regulation to protect the public and the environment from the release of highly hazardous chemicals – elements of the plan can closely track those of OSHA’s Process Safety Management regulation

- Emergency Planning and Community Right to Know Act (40 CFR Part 370) – encourages and supports emergency planning for responding to chemical accidents, and provides local governments and the public with information about possible chemical hazard in their communities.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how