Portable Air Monitor Bump Testing – Quick Tips

The use of portable gas detection devices helps ensure a workplace free from recognized hazards by providing employees working in potentially harmful environments the means to monitor their air quality. Harmful environments may include those with high levels of toxic or combustible gases or oxygen deficient or enriched air. Many of these conditions can’t be detected by smell or sight and therefore require instrumental monitoring to view their levels.

Just as some workers depend on personal protective equipment (PPE) such as safety harnesses/lanyards to help protect them from fall hazards, others depend on an air monitors to help ensure their breathing air is within acceptable levels. Neglecting proper maintenance of this equipment is akin to failing to inspect fall protection equipment. Without maintenance and calibration, users rely on chance to ensure the air-monitoring devices will operate correctly when needed in life-saving applications.

Although air monitors/gas detectors are available with a variety of features and can detect a variety of gases, they have one thing in common: they all need to be maintained, bump tested and calibrated properly on a regular basis. The only way to guarantee the instruments will function accurately is to test them by exposing them to a known concentration of test gas to confirm alarm and sensor functionality.

Bump Testing

A bump test, also known as a functional test, should be performed at the start of each day’s use. This procedure tests the alarms and sensors of a gas detector to be sure they are functional. The test exposes the detector to a known concentration of gases that exceed the lowest alarm set-point for each sensor. The bump test verifies sensor and alarm functionality, but not the accuracy of the instrument (you must rely on calibration for accuracy). To determine which gases are appropriate for your instrument, consult the manufacturer’s instructional manual.

If an instrument fails a bump test, it should immediately go through a complete calibration before being put into use. Although a new gas detector most often is calibrated when sent from the manufacturer, it will still require bump testing/calibrating before it is first put into service to ensure it has not been damaged in shipment. Consult the manufacturer’s instructional manual to determine which process the manufacturer suggests.

Calibration

Calibration is defined by OSHA Bulletin SHIB 09-30-2013 as “an instrument’s measuring accuracy relative to a known concentration of gas. Direct reading portable gas monitors compare the sensor’s response to a known concentration of the test gas.” The Bulletin emphasizes that direct reading portable gas monitors that are properly calibrated can minimize the risk of injury, illness, or death from respiratory hazards such as oxygen deficiency or combustible or toxic gases.

An instrument’s sensors will degrade over time and repeated use. The calibration process allows the instrument the opportunity to self-correct and to reflect the set level of sensor sensitivity. Once a sensor is no longer able to accurately read set values, it has reached the end of its service life and will need to be replaced. Also, any time the detector is dropped or damaged it should be recalibrated.

When purchasing a gas detector/air monitor, you should also purchase several items in order to bump test/calibrate the instrument. Those items may include calibration gases; regulators; tubing; calibration adaptors, cups or caps; and docking/calibration stations.

Calibration Gases: Bump tests/calibrations are only as good as the quality and accuracy of the calibration gases used. Consult the owner’s manual for the type/mixture of gases needed. Be mindful to not use calibration gases that have surpassed the expiration date because the accuracy cannot be guaranteed. Also, some manufacturers may void their warranty if gases other than their brand is used to calibrate the unit.

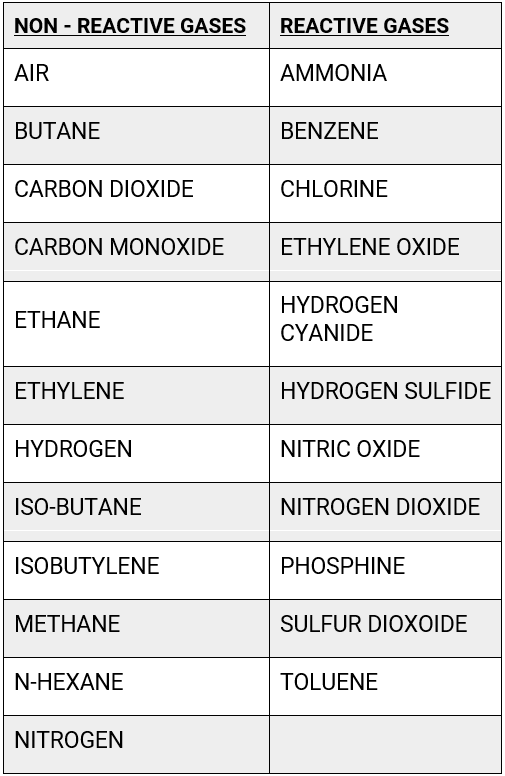

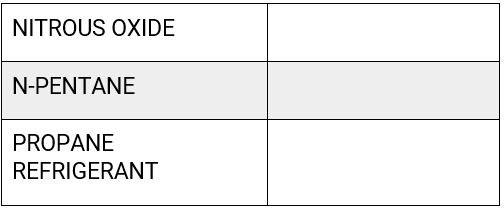

Many cylinder sizes are available. The most common are 17, 29, 34, 58, 76, 103 and 116 liters. The cylinders are made of either aluminum, which house reactive gases, or steel, which store non-reactive gases. Aluminum is shiny in appearance while steel is seen as dull or milky. Below is a list of common non-reactive and reactive gases used in calibration.

The following chart lists which calibration cylinders and regulators are compatible with each other:

Regulators: These are used to control the rate of gas released from the calibration gas cylinders. There are several points to consider when choosing the correct regulator:

- Flow rate: This value is listed in the owner’s manual of your gas detector/air monitor. Using a regulator with the wrong flow rate will decrease the accuracy of bump testing/calibration; it must match the manufacturer’s specifications.

-

- Demand Flow – Pulls gas from the cylinder as needed. Use this type when your instrument has a built-in pump or when performing an automatic calibration using a docking station/calibration station.

- Fixed Flow – Pulls gas from the cylinder at a fixed rate. Use this type when your instrument does NOT have a built-in pump.

- Material type: Use brass for non-corrosive/non-reactive gases. Use stainless steel for corrosive/reactive gases such as ammonia or chlorine.

- Cylinder size: The regulator needs to match the size cylinder you’re using. Be mindful to read the cylinder label to determine the cylinder size if trying to match it to a regulator. Appearances may be deceiving as a manufacturer can vary the wall thickness and pressure the gas is stored under; not all dimensions of cylinders indicate the same capacity.

-

Tubing: Used to capture the calibration gas and funnel it towards the air monitor. It typically comes in three-foot lengths. If using chlorine or ammonia calibration gas, Teflon/FEP tubing is required. It is suggested to change the tubing annually to help ensure it has not been damaged over time.

Calibration adaptor/cup/cap: Used to direct and trap the calibration gas so it flows over the sensors of the instrument. This item most often is included when purchasing the instrument; however, some manufacturers require the item to be purchased separately.

Docking/Calibration Station: Used to house all the calibration equipment in one place and is offered to make the calibration process more convenient. The user docks the monitor and the station runs through a hands-free bump test/calibration process to help prepare the air monitor for use. The items included in each station vary from manufacturer to manufacturer. These stations are not universal and must be used with compatible monitors. Please note: Remember to purchase a demand flow regulator when using a docking/calibration station.

Commonly Asked Questions

Q: How often does a portable gas detector need to be calibrated?

A: To determine how often to calibrate a gas detector; consult the manufacturer’s instructions of the specific instrument. Some manufacturers suggest calibrating the instrument every 30 days; others leave the calibration decision up to the discretion of the end users and/or their safety manager. If entering a permit-required confined space, OSHA mandates calibration of the instrument beforehand in 29 CFR 1910.146(c)(5)(ii)(C). The instrument may have a field entitled “number of days since last calibrated” to help keep track of the last time the unit was calibrated. If a bump test fails, the instrument must go through a full calibration.

Q: What resources are available to help calibrate?

A: Manufacturer specification or user manuals provide step by step instructions to calibrate; see sources below for common manufacturer website links.

Q: How does a bump test differ from calibration?

A: A bump test is a very brief exposure of a monitor to a gas to help verify that the sensors respond and the alarms are functioning. A calibration is performed by exposing the monitor to a certified concentration of gas for a given time to help verify it provides an accurate reading.

Sources

OSHA Safety and Health Bulletin: Calibrating and Testing Direct-Reading Portable Gas Monitors

Honeywell Gas Detection Bump Test and Calibration Frequency

Industrial Scientific Spec Sheets and User Manuals

Industrial Scientific Calibration and Bump Test Recommendations

MSA Datasheets and User Manuals

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how