Performance Oriented Packaging Standard – Quick Tips

On December 21, 1990, the Department of Transportation (DOT) published a final rule under docket HM-181, titled “Performance-Oriented Packaging (POP) Standards; Changes to Classification, Hazard Communication, Packaging and Handling Requirements Based on UN Standards and Agency Initiative.”

In the years following the introduction of this DOT standard, the UN Recommendations that it paralleled have undergone and continue to undergo revisions. Accordingly, the DOT continues to make similar changes to their standard, and records them by the introduction of new dockets. The Code of Federal Regulations (CFR) is also updated regularly to incorporate all dockets that have become final.

How Do You Transport Hazardous Chemicals Safely?

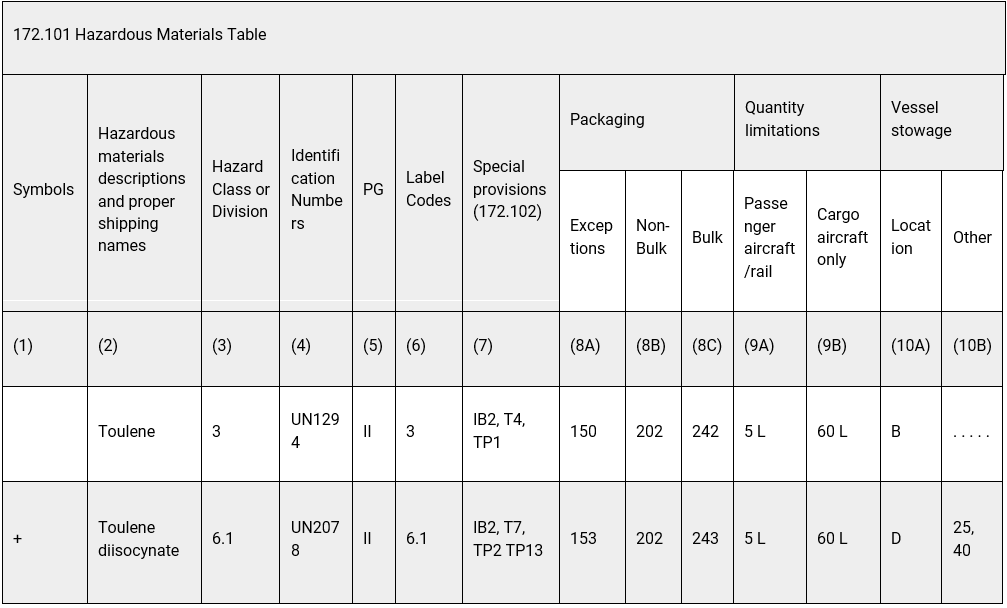

Checking the Hazardous Materials Table located in 49 CFR 172.101 is the first step toward understanding how to ship a product. This table provides the Proper Shipping Name, Hazard Class, Identification Number, Labels and Packaging Types necessary.

First, locate the Proper Shipping Name (PSN). The PSN is listed alphabetically in the Hazardous Materials Table. You must know the technical name in order to do this.

The example below gives a definition for each column of the Hazardous Materials Table. (The example used is toluene.)

Column 1: Symbols — Could contain six symbols: +, A, D, G, I, and/or W.

- The “+” fixes the PSN, hazard class and packaging group for that entry.

- The letter “A” denotes a material that is subject to the requirements only when offered or intended for transportation by aircraft.

- The letter “D” identifies PSNs that are appropriate for domestic shipments.

- The letter “G” identifies PSNs for which one or more technical names of the hazardous material must be entered in parentheses in association with the basic description.

- The letter “I” identifies PSNs for international transport.

- The letter “W” denotes a material that is subject to the requirements only when offered or intended for transportation by vessel.

(In the example, none of these are applicable for toluene.)

Column 2: Hazardous Materials Descriptions and Proper Shipping Names – Lists hazardous materials and their PSNs. Refer to 49 CFR 172.101(c) for further information on Column 2.

(In the example, “toluene” is a PSN.)

Column 3: Hazard Class or Division – Contains a designation of the hazard class or division corresponding to each PSN, or the word “forbidden.” This number is located in the bottom point of the square-on-point labels or placards.

(In the example, toluene is a Class 3.)

Column 4: Identification Number – Lists the identification number assigned to each PSN. One of two prefixes may be found before an actual number:

- “UN” is associated with those PSN considered for international as well as domestic transport.

- “NA” is associated with those PSN recognized for North American shipments only (US and Canada).

(In the example, toluene is UN 1294.)

Column 5: Packing Group (PG) – Specifies one or more packing groups corresponding to the PSN and hazard class for the material. Packing groups I, II and III indicate the degree of danger presented by the material as great, medium or minor, respectively. If more than one packing group is designated for a PSN, the criteria for assigning the packing group is specified in 49 CFR 173 Subpart D.

(In the example, toluene is PG II.)

Column 6: Labels – Indicates which labels by their hazard classes are required for packages containing hazardous materials. If multiple labels are listed, a determination must be made to distinguish the primary hazard from the subsidiary hazards. Refer to the Precedence Table in 49 CFR 173.2a to make this determination. Other labels listed indicate additional hazards associated with the material that can be found in 49 CFR 172.402.

(In the example, toluene requires a flammable liquid label.)

Column 7: Special Provisions – Specifies codes for special provisions applicable to some hazardous materials. The numbers and letters in the special provisions column are referred to in 49 CFR 172.102 with an explanation of their meanings.

(In the example, the special provision codes for toluene are IB2, T4 and TP1.)

Column 8: Packaging Authorization – Column 8A: Exceptions; 8B: Non-Bulk Packaging; and 8C: Bulk Packaging. All numbers that are shown in these columns relate to 49 CFR 173.

(In the example, toluene packaging exceptions are found in 49 CFR 173.150, Non-Bulk Packaging is found in 49 CFR 173.202, and Bulk Packaging is in 49 CFR 173.242.)

Column 9: Quantity Limitations – Columns 9A and 9B specify the maximum quantities that may be offered for transportation in one package by passenger-carrying aircraft or passenger-carrying rail car (Column 9A) or by cargo aircraft only (Column 9B). For further clarification of this column refer to the International Civil Aviation Organization (ICAO) / International Air Transport Association (IATA) guidelines for shipping by air.

(In the example, the Maximum Shipping Quantity for toluene is 5 L and 60 L respectively.)

Column 10: Vessel Stowage Requirements – Column 10A specifies categories for stowage locations onboard cargo and passenger vessels [49 CFR 172.101(k)]. Column 10B specifies codes (found in 49 CFR 176.84) for stowage of specific hazardous materials. For further information regarding sea shipment restrictions refer to the International Maritime Dangerous Goods Code (IMDG).

(In the example, the authorized stowage location for toluene is “Category B”.)

What Are the 9 DOT Hazard Classes?

There are nine hazard classes within the DOT system. Each hazard class is given a specific division number that will define the hazard. Both the hazard class and division are referenced in the Hazardous Materials Table. The following is a breakdown of the hazard classes and divisions:

- Explosives (1.1–1.6)

- Gases (2.1 Flammable, 2.2 Non-Flammable, 2.3 Poison)

- Flammable Liquids (Class 3)

- Solids (4.1 Flammable, 4.2 Spontaneously Combustible, 4.3 Dangerous When Wet)

- Oxidizing Agents (5.1 Oxidizer, 5.2 Organic Peroxide)

- Poisons (6.1 Poisonous Materials 6.2 Infectious Substance (Etiologic Agent))

- Radioactive (Radioactive I, Radioactive II, Radioactive III), Fissile, Empty Packages (Class 7)

- Corrosive (Class 8)

- Class 9

Hazardous Materials Markings, Labels, Placards

The contents of a shipment must be thoroughly identified through shipping papers and marking, labeling and placarding of the shipment. (The necessity of these three forms of identification depends largely on the size of the shipment. Refer to the Hazardous Materials Table, 49 CFR 172.101.)

Markings:

A marking is a handwritten or a pre-printed, self-adhesive label containing the following required information: PSN, the UN/NA identification number, and the consignee’s or consignor’s name and address (49 CFR 172.301).

Labels:

Hazardous shipping labels are specific to the hazard classes of materials and have strict specifications for setup including color, size and wording, as well as placement on a package (49 CFR 172 Subpart E). A label chart that shows hazard class or division and the associated label plus the section reference can be found in 49 CFR 172.400(b). If two labels are listed in the label column, the less hazardous of the two is a secondary hazard. This secondary hazard must also be labeled per 49 CFR 172.402.

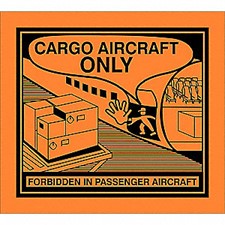

Another form of labeling is the use of Special Precautions Labels. These labels have specifications for setup in the CFR and are intended for specific situations. Some examples of these labels are Empty, and Cargo Aircraft Only.

Labels must be durable and weather resistant. They must be able to withstand, without deterioration or a substantial change in color, a 30-day exposure to conditions incident to transportation that reasonably could be expected to be encountered by the labeled package. Labels must meet the specifications detailed in 49 CFR 172.407.

Depending on the nature and quantity of the shipment, placarding completes the shipment identification process. Placards are larger than labels, and must measure at least 9.84 inches on each side. Placards are also specific to the hazard class of materials. The specifications are equally strict for color, size and wording, as well as placement on a shipping vehicle (49 CFR 172 Subpart F). Two tables (Table 1 and Table 2) help determine if placards are necessary (49 CFR 172.504). Placarding for subsidiary hazards is also required (similar to labeling) and is detailed in 49 CFR 172.505.

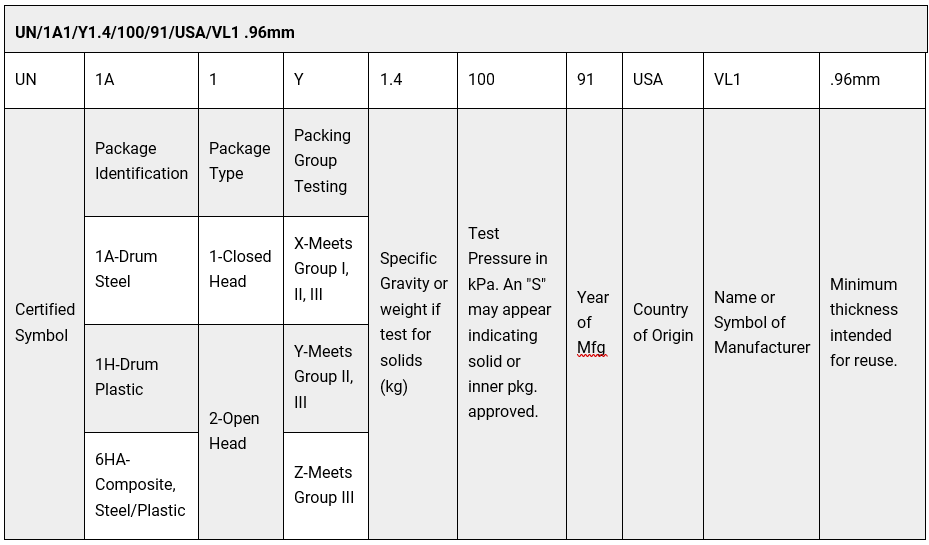

Containers

Container manufacturers must test and mark non-bulk packaging according to UN Standards. The markings must be durable, legible and placed according to 49 CFR 178 Subpart L. Note: This criteria is specific only to the drum. To find compatibility information specific to the chemical you must refer to the Safety Data Sheet (SDS) or contact the manufacturer of the chemical.

DOT Hazardous Materials Training:

US DOT “hazmat employee” training requirements apply to any company with employees who perform any function in any way regulated by the US DOT Hazardous Materials Regulations (HMR) found in 49 CFR. This includes any company with employees who:

- Offer hazardous materials for transportation

- Package, mark, or label hazardous materials for transportation

- Load or unload hazardous materials transport vehicles

- Transport hazardous materials

- Receive and forward packages containing hazardous materials

- Manufacture packaging for use in transporting hazardous materials

- Test hazardous material packaging

Employers determine the level and details of training based on a hazmat employee’s job functions. The DOT does, however, require certain categories of training.

- General Awareness Training: At a minimum, all hazmat employees must be given a general understanding of the entire hazardous materials transportation program, so that they know how their jobs fit into the system.

- Function-specific Training: All hazmat employees must also be trained on any specific job functions that they perform in relation to the hazardous materials regulations.

- Safety Training: Persons handling or potentially exposed to hazardous materials during the cycle of transportation must be trained in safe handling and emergency response procedures applicable to the hazards to which they may be exposed.

- Security Awareness Training: All hazmat employees must be trained to recognize and protect against potential terrorist threats involving hazardous material shipments.

- Security Plan Training: Each hazmat employee preparing or transporting certain high-risk shipments [49 CFR 172.800(b)] must also be trained in company security objectives, organizational structure and specific procedures, and responsibilities or actions required from them.

Specific requirements for training of hazardous materials drivers are found at 49 CFR Part 177 and Parts 350-399.

Commonly Asked Questions

Q: How often must hazmat employee training be updated or repeated?

A: Hazmat employee training must be repeated in its entirety at least every three years [49 CFR 172.704(c)(2)]. This “recurrent” training must include testing and formal recordkeeping. If an employee has not been retrained within the past three years, that employee cannot perform any hazmat employee functions until trained.

Q: Do the Hazard Communication standard pictograms and DOT labels conflict with each other?

A: No. The DOT aligned with the Hazard Communication standard’s physical hazard criteria in 2008 in order to classify hazards for toxic materials and flammable liquids during the transport of hazardous chemicals. The DOT and the Occupational Safety and Health Administration (OSHA) are using the same criteria for physical hazards.

Q: Can I create customized shipping labels?

A: Labels are federally regulated. Additional information can be added to a label as long as it does not change anything within the 3.9″ x 3.9″ space. The classification code can be added to the explosive labels. 4″ x 41/2″ labels can be used if a chemical name and chemical identification number need to be displayed.

Sources

49 CFR Subtitle B Chapters I and III

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how