Osha’s Bloodborne Pathogens Standard – Quick Tips

The Occupational Safety and Health Administration (OSHA) bloodborne pathogens standard applies to all persons who may reasonably anticipate contact with blood or other potentially infectious materials (OPIMs) in the course of their employment. Within the standard, OPIMs are defined as, “semen, vaginal secretions, cerebrospinal fluid, synovial fluid, pleural fluid, pericardial fluid, peritoneal fluid, amniotic fluid, saliva in dental procedures, any body fluid that is visibly contaminated with blood, and all body fluids in situations where it is difficult or impossible to differentiate between body fluids.” Occupational exposure means reasonably anticipated skin, eye, mucous membrane, or parenteral (needlestick) contact with blood or OPIMs.

The core requirement of the regulation is the creation of a written exposure control plan that describes how the employer will eliminate or minimize occupational exposures to blood or OPIMs. At a minimum, the following three elements must be present in an exposure control plan: (29 CFR 1910.1030(c)(1)(ii)):

Exposure determination

- A listing of all job classifications in which employees will be exposed (e.g., doctors and nurses) or may occasionally be exposed, such as custodians and laundry workers, to blood or OPIMs. Specific procedures or tasks in which exposure could occur must also be listed (29 CFR 1910.1030(c)(2)).

- The schedule and method of implementation for methods of compliance, human immunodeficiency virus (HIV) and hepatitis B virus (HBV) research laboratories and production facilities, hepatitis B vaccination and post-exposure evaluation and follow-up, communication of hazards to employees, and recordkeeping (29 CFR 1910.1030 (d – h).

- The procedure for the evaluation of circumstances surrounding exposure incidents (29 CRR 1910.1030 (f)(3)(i)).

The exposure control plan must be updated annually to reflect changes in tasks, procedures, and positions that affect occupational exposure, and also technological changes that eliminate or reduce occupational exposure.

Other key requirements of the standard also include:

- Providing education and training

- Providing personal protective equipment (PPE)

- Identifying and use of engineering controls

- Making hepatitis B vaccination available to workers with occupational exposure

- Making available post-exposure evaluation and follow-up to any occupationally exposed worker who experiences an exposure incident

- Proper waste disposal

- Communication of hazards

- Housekeeping and laundry practices

- Recordkeeping

Employee Education and Training

Annual training covering the following is required (29 CFR 1910.1030(g)(2)(vii)):

- An accessible copy of the regulatory text of the standard and an explanation of its contents;

- A general explanation of the epidemiology and symptoms of bloodborne diseases;

- An explanation of the modes of transmission of bloodborne pathogens;

- An explanation of the employer’s exposure control plan and the means by which the employee can obtain a copy of the written plan;

- An explanation of the appropriate methods for recognizing tasks and other activities that may involve exposure to blood and OPIMs;

- An explanation of the use and limitations of methods that will prevent or reduce exposure including appropriate engineering controls, work practices, and PPE;

- Information on the types, proper use, location, removal, handling, decontamination and disposal of PPE;

- An explanation of the basis for selection of PPE;

- Information on the HBV vaccine, including information on its efficacy, safety, method of administration, the benefits of being vaccinated, and that the vaccine and vaccination will be offered free of charge;

- Information on the appropriate actions to take and persons to contact in an emergency involving blood or OPIMs;

- An explanation of the procedure to follow if an exposure incident occurs, including the method of reporting the incident and the medical follow-up that will be made available;

- Information on the post-exposure evaluation and follow-up that the employer is required to provide for the employee following an exposure incident;

- An explanation of the warning signs and labels and/or color coding; and

- An opportunity for interactive questions and answers with the person conducting the training session.

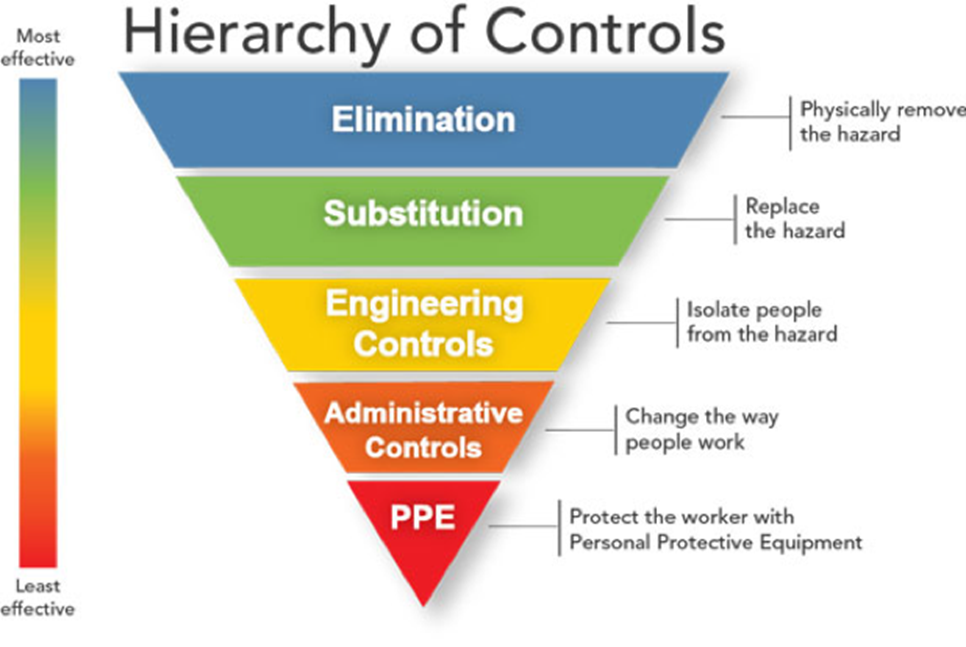

Preventing Exposure – Hierarchy of Hazard Controls

Preventing exposure to bloodborne pathogens is critical. According to the National Institute of Occupational Safety and Health’s (NIOSH’s) hierarchy of hazard controls, the first strategy is to implement engineering measures to eliminate or control the hazard at its source. The next level of control is administrative and work practice controls. Administrative controls are measures aimed at reducing employee exposure to hazards. Examples of administrative controls include the use of relief workers and worker rotation. Safe work practices include general workplace rules and operation-specific rules. When engineering controls are not feasible (while they are being instituted or in an emergency situation), PPE must be used.

Engineering and Administrative Control Measures

Employers must take appropriate preventative measures to prevent occupational exposure to blood or OPIMs. Engineering controls include biohazard fume hoods, puncture-resistant sharps containers, biohazard waste containers, mechanical pipette devices and others to permanently remove the hazard or help isolate the worker from exposure. These also include needleless devices, needles with sheaths and blunt suture needles. As new devices become available due to updated technologies, they should be incorporated as engineering controls.

Work practice controls include hand-washing policies, sharps handling procedures, proper waste disposal techniques and more to reduce the likelihood of exposure through the alteration of the manner in which the task is performed (29 CFR 1910.1030(d)(2)).

Provide PPE

Employers must provide PPE to employees to minimize the risk of exposure to blood or OPIMs. PPE is appropriate only if it does not permit blood or OPIMs to pass through or reach the employees’ outer clothing, undergarments, skin, eyes, mouth or other mucous membranes under normal conditions of use. Following is a list of suggested PPE and when it should be used:

- Gloves: Wear whenever hand contact with blood or OPIMs is possible. Disposable (single-use) gloves, such as examination gloves, must be replaced as soon as possible when contaminated or when their ability to function as a barrier is compromised. They are not to be reused (29 CFR 1910.1030(d)(3)(ix)(A)). Utility gloves can be reused if decontaminated, but must be discarded if cracked, discolored, punctured or showing any signs of deterioration (29 CFR 1910.1030(d)(3)(ix)(c)).

- Masks, eye protection and face shields: Use in combination whenever splashes, spray or droplets of potentially infectious materials are generated (29 CFR 1910.1030(d)(3)(x)).

- Gowns, aprons and other protective clothing: Wear when exposure to the body, head, feet, or clothing is possible. The type and characteristics of the covering will depend on the task and the exposure anticipated (29 CFR 1910.1030(d)(3)(ix)).

- Cardiopulmonary resuscitation (CPR) masks: Use when CPR is given. Masks or face shields should have a one-way valve to prevent contamination from the victim (29 CFR 1910.1030(d)(3)(i)).

HBV Vaccinations

Once employees receive training, HBV vaccinations should be made available to those who run the risk of exposure to contaminated blood and OPIMs (29 CFR 1910.1030(f)(2)).

Post-Exposure Evaluation and Follow-Up

Employers must provide a confidential medical evaluation for any employees involved in an exposure incident. The purpose of this evaluation is to document the exposure route and circumstances surrounding the incident, blood testing, HIV/HBV status of source and appropriate medical and psychological treatment (29 CFR 1910.1030(f)(3))

Waste Disposal

All blood or OPIMs contaminated items that could release infectious materials must be placed in appropriate sharps containers or closable, color-coded or properly labeled leak-proof biohazard waste containers or bags. OPIM waste must be disposed of in accordance with federal, state and local regulations (29 CFR 1910.1030(d)(4)(iii)).

Communication of Hazards

Warning labels must be attached to all containers used for the storage or transport of potentially infectious materials. The labels must be orange or red-orange with the biohazard symbol in a contrasting color. Red containers or bags can be substituted for warning labels (29 CFR 1910.1030(g)).

Housekeeping and Laundry Practices

Employers must create a schedule for periodic cleaning and appropriate disinfecting to ensure that the worksite is kept clean and sanitary. Contaminated laundry must be placed and transported in properly labeled or color-coded bags and containers (29 CFR 1910.1030(d)(4)), (29 CFR 1910.1030(d)(4)(iv)).

Recordkeeping

The employer must maintain medical and training records for each employee who faces the possibility of being exposed or who has been occupationally exposed to a bloodborne pathogen (29 CFR 1910.1030(h)). Employers are also required to establish and maintain a sharps injury log.

Sources

29 CFR 1910.1030, Bloodboorne Pathogens Standard

OSHA Fact Sheet, OSHA’s Bloodborne Pathogens Standard, 2011

Centers for Disease Control and Prevention (CDC) Bloodborne Infectious Disease Page

Frequently Asked Questions

Q: What are sharps disposal containers?

A: A sharps container is a place to deposit sharp instruments (e.g., needles or cutting tools/blades) for disposal. These containers are puncture-resistant, leak-proof on the sides and bottom, closable and properly labeled or color-coded. They assure a higher level of safety than disposal bags.

Q: Can biohazard bags or containers be both labeled and color-coded?

A: Yes, OSHA’s bloodborne pathogens standard states that containers must be either properly labeled or color-coded. Having both simply exceed the intent of the regulation.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how