OSHA Scaffolding Requirements – Quick Tips

The very presence of scaffolding at a job site creates a hazardous work environment. Falls, falling objects and structure instability are all dangerous possibilities and pose a threat to safety in the workplace. The Occupational Safety and Health Administration’s (OSHA’s) construction scaffolding requirements and the 1996 revisions to 29 Code of Federal Regulations (CFR) 1926 Subpart L make working on or around scaffolding safer.

Originally adopted in 1971, OSHA’s first construction scaffolding requirements remained relatively unchanged until 1996. The 1996 revisions are performance-based, which means the standards do not tell users specifically what to do. Performance-based standards provide guidelines and may specify some requirements, but in general, the “how to” part of the equation is left up to the user. The specifics of compliance depend on the types of scaffolding being used, the situations they are used in and the personnel using them.

The 1996 revisions also addressed types of scaffolding not previously mentioned, the greater variety of personal fall protection systems available and training.

In November 2016 revisions to OSHA’s general industry Walking and Working Surfaces Standard (29 CFR 1910 Subpart D) were finalized. Several revisions were made including the removal of all existing general industry scaffolding requirements. Employers are now required to comply with the construction industry standards in 29 CFR 1926 Subpart L. This is codified under 29 CFR 1910.27(a).

This document focuses on three key topics covered in 29 CFR 1926 Subpart L – training, fall protection and working safe distances from energized power lines.

For additional information, visit OSHA’s Scaffolding Safety and Health Topics page, eTool. and 29 CFR 1926 Subpart L.

Because of the complexity and size of 29 CFR 1926 Subpart L, this document will only discuss three topics: training, fall protection and working safe distances from energized power lines.

Training

When OSHA revised its Scaffolds standard in 1996, the Bureau of Labor Statistics (BLS) studies showed that 25% of workers injured in scaffold accidents had received no scaffold safety training. To prevent this from continuing, OSHA strengthened the training requirements.

Training requirements are discussed in 29 CFR 1926.454. Employers must have each employee who performs work while on a scaffold trained by a person qualified in the subject matter to recognize the hazards associated with the type of scaffold being used and to understand the procedures to control or minimize those hazards Qualified means one who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience, has successfully demonstrated his/her ability to solve or resolve problems related to the subject matter, the work, or the project.

- The nature of any electrical hazards, fall hazards and falling object hazards in the work area;

- The correct procedures for dealing with electrical hazards and for erecting, maintaining and disassembling the fall protection systems and falling object protections systems being used;

- The proper use of the scaffold and the proper handling of materials on the scaffold;

- The maximum intended load and the load-carrying capacities of the scaffolds used; and

- Any other pertinent requirements.

Fall Protection

Per 1926.451(g)(1), OSHA has determined a fall protection threshold of 10 feet for scaffolding (also note American National Safety Institute A10.8-2011). This threshold differs from Subpart M (fall protection), which requires the use of fall protection at six feet for most construction activities. Different thresholds are required because scaffolds are temporary structures erected to aid workers who are constructing or demolishing other structures, and scaffolds are less amenable to the use of fall protection at the time the first level is erected.

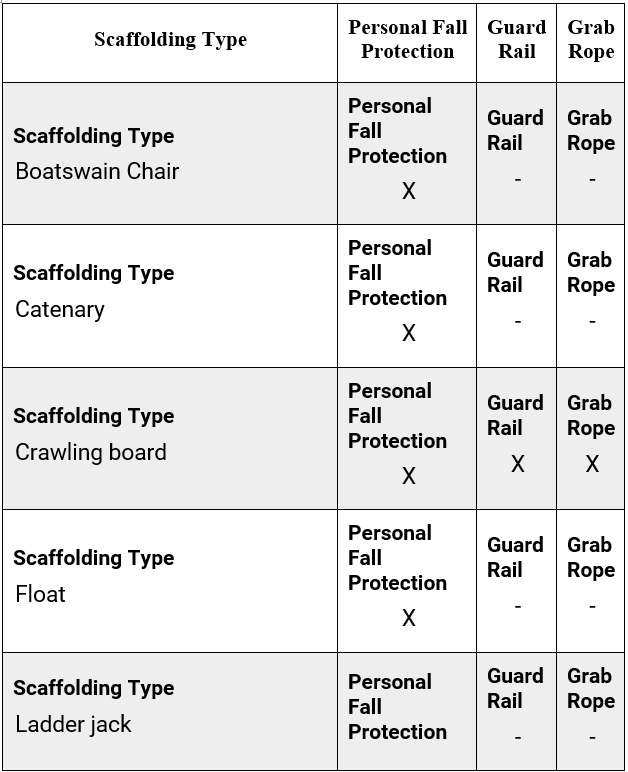

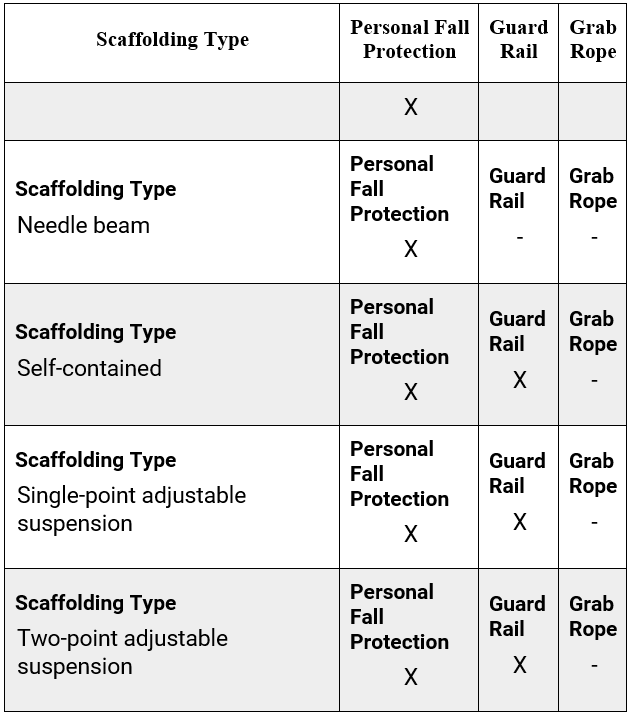

Table 1 details the types of fall protection needed with specific types of scaffolding.

Table 1

Employers are responsible for providing fall protection and ensuring its use. Since September. 2, 1997, employers have been required to have a competent person determine whether fall protection is necessary and feasible for employees erecting or dismantling supported scaffolds. Supported scaffolds consist of one or more platforms supported by rigid, load-bearing members, such as poles, legs, frames, outriggers, etc. Competent person means one who is capable of identifying existing and predictable hazards in the surroundings or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to take prompt corrective measures to eliminate them.

Safe Distances from Energized Power Lines

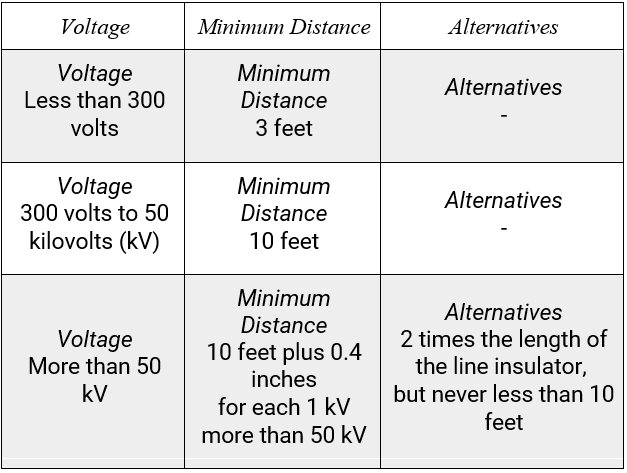

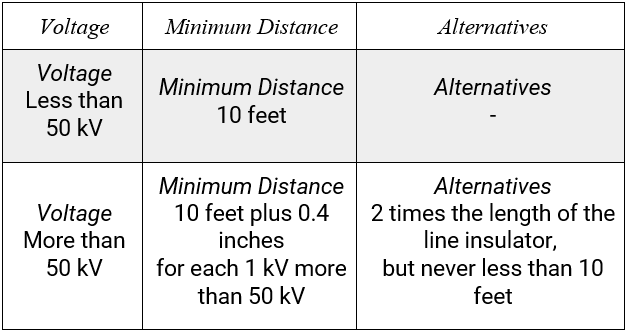

Per 29 CFR 1926.451(f)(6), scaffolds cannot be erected, used, dismantled, altered or moved closer than the distances stated below in Table 2 when near energized power lines.

Table 2 Insulated Lines

Uninsulated Lines

However, scaffolds can be moved closer if it is necessary for the performance of work, provided the power lines are de-energized or protective coverings are installed to help prevent accidental contact. For more information, refer to 29 CFR 1926.451(f)(6) Exception.

Commonly Asked Questions

Q: What types of equipment are recommended for a personal fall protection system?

A: A personal fall protection system consists of an anchorage point, body belt or body harness and might include a lanyard, deceleration device, lifeline or a combination of these.

Q: Are extension cords considered exposed power lines?

A: No. Extension cords and power tool cords are not included in the definition of an exposed power line.

Sources

29 CFR 1910.27 Scaffolds and Rope Decent Systems

OSHA Safety and Health Topics – Scaffolding

Scaffolding Hazards and Possible Solutions

29 CFR 1926.451 Scaffolds – General Requirements

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how