Mobile Work Platforms – Quick Tips

Introduction

Changes to the American National Standards Institute (ANSI) / Scaffold and Access Industry Association (SAIA) A92 standards have created a new “normal” for equipment formerly known as aerial lifts, aerial work platforms (AWPs), manlifts, powered platforms and vehicle-mounted work platforms. They are all now referred to as mobile elevating work platforms (MEWPs).

The ANSI standards have for many decades provided best practices for safe, reliable access to work at height. They have always identified the responsibilities for manufacturers, dealers, users, occupants and operators. However, the revised suite of A92 standards places a huge emphasis on the responsibilities of the user — typically the employer.

Definitions

Dealer: An entity who buys, rents or leases from a manufacturer or distributor and who generally sells, rents and services MEWPs.

Manufacturer: An entity who makes, builds or produces a MEWP.

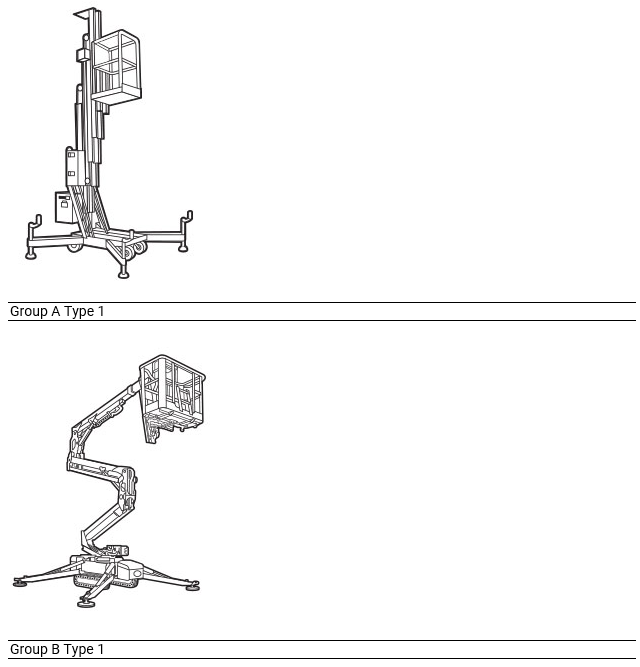

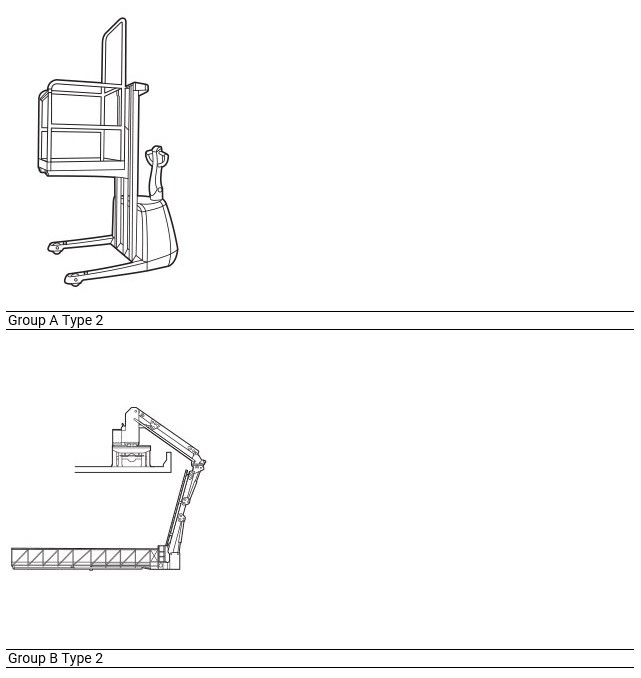

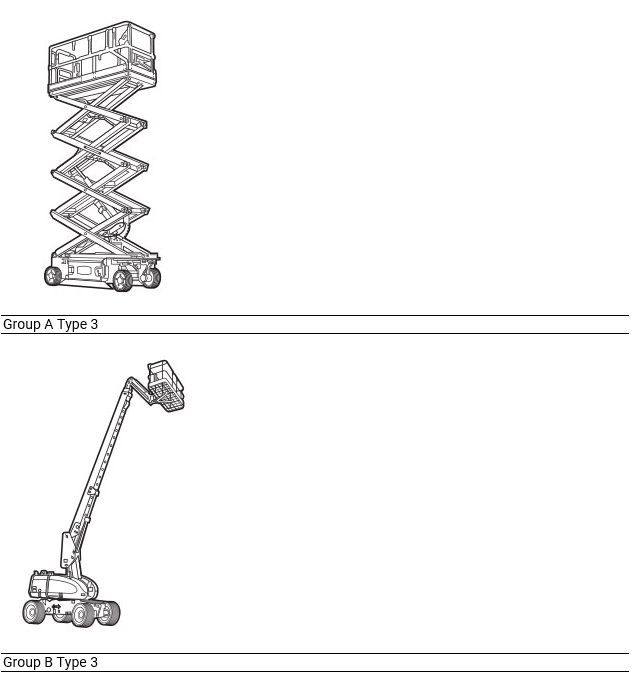

Mobile Elevating Work Platform (MEWP): Machine/device intended for moving persons, tools and material to working positions, consisting of at least a work platform with controls, an extending structure and a chassis. MEWPs are classified into two groups:

- Group A: MEWPs with platforms that move vertically but stay inside the tipping lines

- Group B: All other MEWPs, typically boom-type MEWPs where the platform extends past the machine’s chassis.

Under each group, they are then classified into types:

- Type 1: Can only be driven in the stowed position

- Type 2: Can be driven elevated but is controlled from the chassis

- Type 3: Can be driven elevated but is controlled from the work platform

Types 1 and 3 are the most commonly used MEWPs.

Occupant: An entity on the work platform.

Operator: An entity qualified to control the movement of a MEWP.

User: An entity that has care, custody and control of the MEWP.

Work platform: Component of the MEWP intended for carrying personnel along with their necessary tools and materials.

Revised Suite of ANSI/SAIA A92 Standards

Within the Occupational Safety and Health Administration (OSHA) Construction standards – 29 Code of Federal Regulations (CFR) 1926 Subpart L and General Industry standards (29 CFR 1910 Subpart F) the design and construction of aerial lifts meeting ANSI A92.2 is addressed:

- 29 CFR 1926.453(a)(1)“…aerial lifts acquired for use on or after January 22, 1973 shall be designed and constructed in conformance with the applicable requirements of the American National Standards for “Vehicle Mounted Elevating and Rotating Work Platforms,” ANSI A92.2-1969, including appendix.”

- 29 CFR 1910.67(b)(1)“…aerial devices (aerial lifts) acquired on or after July 1, 1975, shall be designed and constructed in conformance with the applicable requirements of the American National Standard for “Vehicle Mounted Elevating and Rotating Work Platforms,” ANSI A92.2—1969, including appendix.”

The revised suite of ANSI/SAIA A92 standards now include:

- ANSI/SAIA A92.2-2015, American National Standard for Vehicle-Mounted Elevating and Rotating Aerial Devices

- ANSI/SAIA A92.20-2020, Design Calculations, Safety Requirements, and Test Methods for Mobile Elevating Work Platforms (MEWPs)

- This Standard focuses on the design, calculations, safety requirements and testing methods for mobile elevating work platforms (MEWPs). It serves as a guide for manufacturers and engineers so they can build compliant machines. Load sensing, wind force requirements, tire types, tilt sensing requirements, height of folding rails, and machine markings and documentation are addressed. Older machines do not need to be retrofitted to meet the new standards.

- ANSI/SAIA A92.22-2020, Safe Use of Mobile Elevating Work Platforms (MEWPs)

- This Standard governs the safe use of MEWPs by specifying proper application, inspection, training, maintenance, repair and safe operation. One of the main requirements is developing a safe use program to guide MEWP use as it relates to job site safety. To develop an effective compliant safe use program, first a site risk assessment must be conducted. The assessment should define the task, location and timing of the work; specify the MEWP to be used; and identify training and rescue planning needs. Once a safety plan has been developed, it should be shared with everyone who will be on site during the work. This Standard mostly impacts safety managers, supervisors, and MEWP operators and clear communication of developed safety plans amongst them is key.

- ANSI/SAIA A 92.24-2018, Training Requirements for the Use, Operation, Inspection, Testing, and Maintenance of Mobile Elevating Work Platforms (MEWPs)

- This Standard focuses on training requirements and primarily impacts end users and dealers. It provides guidance on preparing training materials, defines how training should be delivered, and identified required training elements. According to the standard, all training must be delivered by a qualified person who is experienced with the class of MEWP being trained on. The qualified trainer must be knowledgeable on the laws, regulations, safety use practices, manufacturer’s requirements and recognition and avoidance of hazards. Operators and others who will be in contact with the MEWP must be trained. Others include supervisors – those who directly supervise MEWP operators, and occupants – those on the work platform who are not considered operators.

The following ANSI/SAIA standards were withdrawn on the effective dates of the A92.20, A92.22 and A92.24 standards:

- ANSI A92.3-2006 (R2014) Manually Propelled Elevating Aerial Platforms

- ANSI A92.5-2006 (R2014) Boom-Supported Elevating Work Platforms

- ANSI A92.6-2006 (R2014) Self Propelled Elevating Work Platforms

- ANSI A92.8-2015 Vehicle Mounted Elevating and Rotating Aerial Platform

Fall Protection

OSHA’s fall protection requirements are found in 29 CFR1 926 Subpart M, 1926.500 – 503 and 2CFR 1910 Subparts D, F and I, 1910.23, .66, .67 and .140.

According to ANSI/SAIA A92.22 standard the primary means of fall protection on all MEWPs is provided by the guardrail system. If personal fall protection is required, either fall restraint or fall arrest, operators and occupants must comply with the instructions provided by the manufacturer regarding anchorage(s). All Group B MEWP operators and occupants must use personal fall arrest or fall restraint systems at all times.

Per ANSI/SAIA A93,22 a fall restraint system restrains or prevents a worker from being exposed to a fall. The following type of fall protection equipment can be used for fall restraint: a short or adjustable restraint lanyard and a body belt or a full-body harness. However, this system prevents freedom of movement for the worker.

A fall arrest system is designed to arrest the fall of a worker. They are designed to provide freedom of movement for the worker. The following type of fall protection equipment can be used for fall arrest: a self-retracting lifeline and a full body harness. Personal fall arrest systems must be rigged so that an employee cannot free fall more than six feet or allow the worker to come in contact with a lower surface.

Determining the correct fall protection system should be based on a risk assessment and evaluated by a competent person as defined in 29 CFR 1910.66 Appendix C. There are several fall clearance calculators that can be used to determine the safe fall distance.

References

- 29 CFR 1926.453, Aerial Lifts

- 29 CFR 1926 Subpart M Fall Protection

- 29 CFR 1910 Subpart DWalking-working surfaces

- 29 CFR 1910.66, Powered Platforms for Building Maintenance

- 29 CFR 1910.67, Vehicle-Mounted Elevating and Rotating Work Platforms

- 29 CFR 1910.140 Personal Fall Protection Systems

- ANSI/SAIA A92.2-2015, American National Standard for Vehicle-Mounted Elevating and Rotating Aerial Devices

- ANSI/SAIA A92.20-2020, Design Calculations, Safety Requirements, and Test Methods for Mobile Elevating Work Platforms (MEWPs)

- ANSI/SAIA A92.22-2020, Safe Use of Mobile Elevating Work Platforms (MEWPs)

- ANSI/SAIA A 92.24-2018, Training Requirements for the Use, Operation, Inspection, Testing, and Maintenance of Mobile Elevating Work Platforms (MEWPs)

Commonly Asked Questions

Q: Can I use a body belt on a mobile elevating work platform (MEWP)?

A: Yes, as long as the body belt is used as part of a positioning device system and the worker cannot fall more than two feet [29 CFR 1926.502(e)(1)]. For fall distances greater than two feet, a full body harness must be used. A positioning device system means a body belt or body harness system rigged to allow an employee to be supported on an elevated vertical surface, such as a wall, and work with both hands free while leaning.

Q: Can any self-retracting lifeline be used with MEWP equipment?

A: The selected self-retracted lifeline must be one that the manufacturer has approved for use with the specific MEWP equipment. Some self-retracting lifelines are not designed to have the anchorage point below the connection point on the wearer.

Q: Can the MEWP guardrails be used as an anchorage point?

A: The guardrails should not be used as an anchorage point unless they have been specifically designed to do so by the MEWP manufacturer and instructions for use have been supplied in the operator’s manual.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how