Lift Plan for Critical Lifts

Think of crane safety as a triangle. One side is the written crane, hoist, and rigging policy, which includes requirements for frequent and periodic inspections.

Think of crane safety as a triangle. One side is the written crane, hoist, and rigging policy, which includes requirements for frequent and periodic inspections.

The second side of the triangle are the supervisors, qualified and trained operators, and any designated or authorized persons qualified to operate or work around the crane.

The third side is the lift plan. Most crane collapses, failures, injuries, and deaths can be prevented by using a lift plan. All lifts require at least some planning – how much does the load weigh, what’s the capacity of the crane – but critical lifts require more planning and oversight to ensure a safe and successful lift.

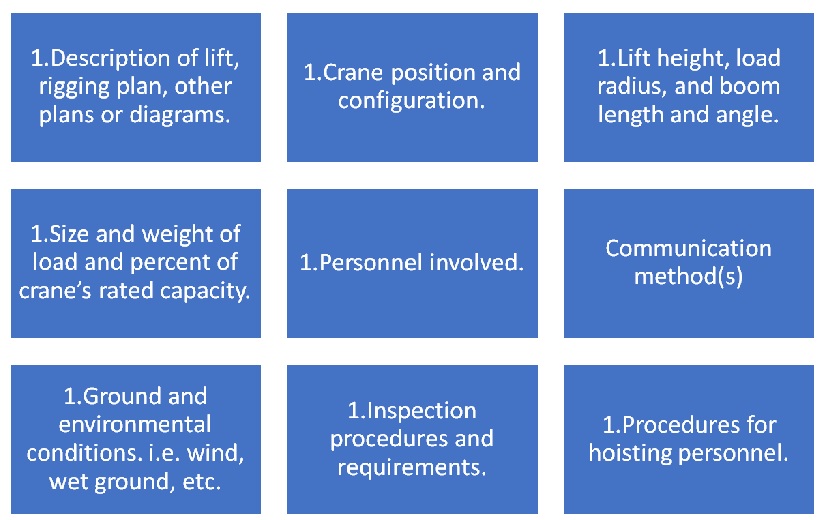

There are many definitions of what a critical lift is. A common definition is a lift that exceeds 75 percent of the crane’s maximum rated capacity. Here are the common components of a lift plan.

Components of a Lift Plan

Pre-Lift Review

Hold a pre-lift meeting with the crane operator, lift supervisor, rigger and anyone else involved. The critical lift plan should be reviewed to ensure the team is ready to safely conduct the lift. Whenever possible, a practice lift with similar crane configurations and load conditions should be done. Remember, practice lifts should always be performed by the same crew, using the same lifting equipment, as those used for the lift.

Hoisting Personnel

Hoisting workers must only occur if there is not a safer way to access an elevated work area and these requirements are followed.

The total weight of the load must not exceed 50% of the crane’s load chart capacity. The weight of the platform and rated safe working load weights must be conspicuously and permanently marked on the platform.

A positive locking safety latch must be on the crane hook and load lines must have a safety factor of at least seven times the maximum intended load. Guard rails must be provided with a locking gate that does not swing outward.

Proof testing at 125% of the platform’s rating capacity is required prior to hoisting employees and after any repair or modification. Whenever the crane is moved to a new location, a new proof test is required.

A proper tie-off to a structural member inside the basket or the lower load block/overhaul ball should be reviewed during the pre-lift meeting.

The platform during the unmanned trial lift must be loaded to at least to the expected lift weight should be made from ground level to each location at which personnel will be hoisted.