Ladder Requirements

According to the Centers for Disease Control and Prevention (CDC), across all workers, approximately 20% of all fall injuries involve a ladder. Among construction workers – especially roofing, framing, siding, and painting contractors – the dangers of ladder falls are even more clear: An estimated 81% of fall injuries treated in emergency rooms across the country involve a ladder. Construction has the highest rate of ladder fall injuries of any industry.

Ladders come in a variety of shapes, sizes, and materials. They are useful in many industries for a variety of applications. This document offers an overview of the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) Accredited Standards Committee (ASC) standards for ladders, along with tips for proper ladder usage. A critical component of fall prevention is making sure all ladders meet OSHA and ANSI-ASC standards. Read on to see if yours pass the test.

OSHA Regulatory Requirements

In late 2016, OSHA published an update to its walking-working surface rule (subpart D) for general industry. Subpart D applies to all general industry workplaces and covers all walking-working surfaces unless specifically excluded by an individual section of the subpart. Specifically, the update incorporates advances in technology, industry best practices and national consensus standards to provide effective and cost-efficient worker protection addressing slip, trip and fall hazards.

The update ushered in some sweeping changes where ladders were concerned. As part of the update, OSHA combined its previously separate regulations for portable wood ladders, portable metal ladders and fixed ladders under one comprehensive ladder standard: 29 Code of Federal Regulations (CFR) 1910.23 which applies to all ladders used in general industry with a few exceptions. Those exceptions are ladders used in emergency operations such as firefighting, rescue and tactical law enforcement operations, or training for those operations, and ladders that are an integral part of a machine or piece of equipment.

The four main components of OSHA’s ladder standard cover:

- General Requirements for all ladders

- Portable Ladders

- Fixed Ladders

- Mobile Ladder Stands and Mobile Ladder Stand Platforms

Under the General Requirements for all ladders, 29 CFR 1910.23(b)(11-13), OSHA addresses proper ladder climbing technique When ascending or descending a ladder, employees must always maintain three points of contact by:

- Facing the ladder

- Using at least one hand to firmly grasp the ladder

- Not carrying any object or load that could cause them to lose balance and fall

Employers are required to ensure that every employee follows this climbing technique.

The General Requirements for all ladders also covers the design specifications for rungs and steps used on ladders and stepstools. The design for rungs and steps must meet the following criteria:

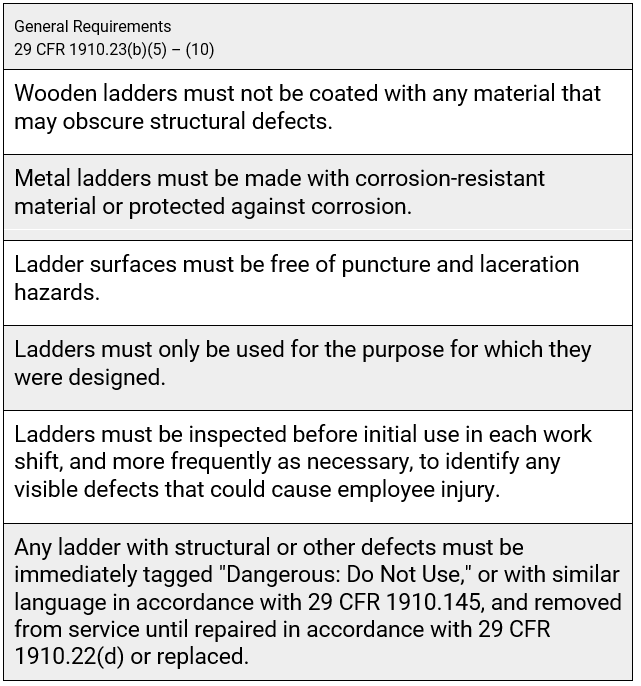

In addition, the General Requirements for all ladders mandate the following:

Portable Ladders

OSHA defines a portable ladder as one that can readily be moved or carried, usually consisting of side rails joined at intervals by steps, rungs, or cleats.(29 CFR 1910.21(b)). They can be self-supporting or lean against a supporting structure (non-self-supporting).

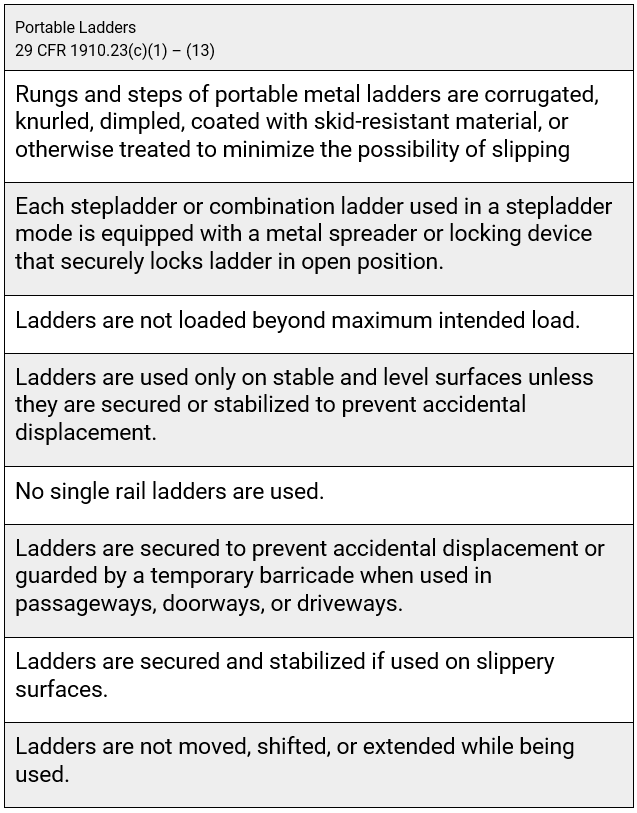

Employers must ensure that:

Fixed Ladders

OSHA defines a fixed ladder as a ladder with rails or individual rungs that is permanently attached to a structure, building or equipment (29 CFR 1910.21(b)). These do not include ship stairs, step bolts, or manhole steps.

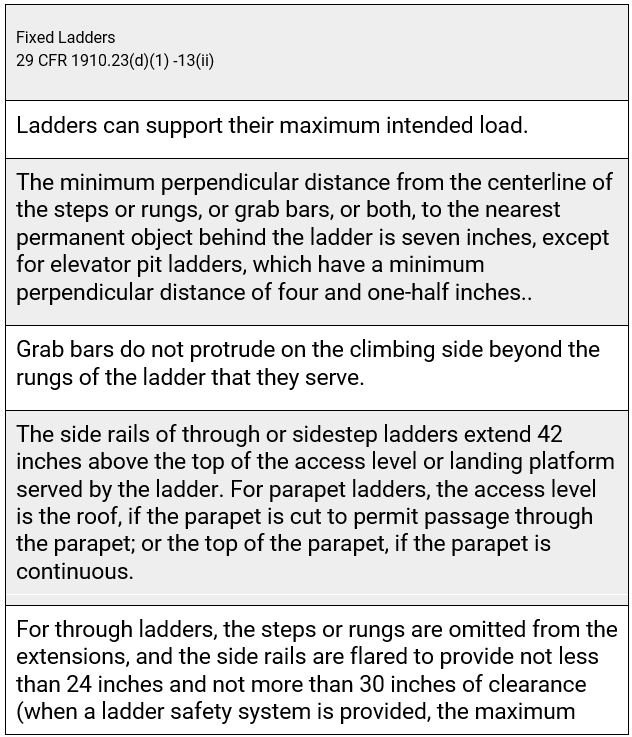

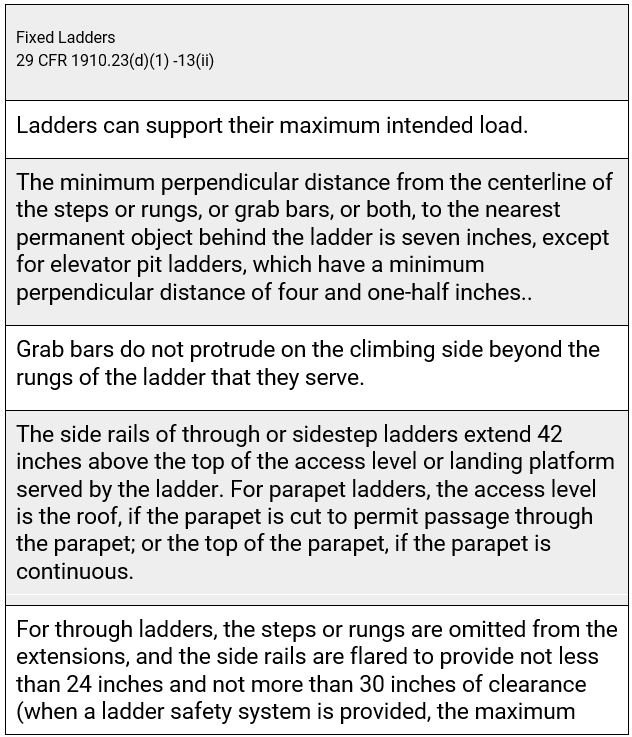

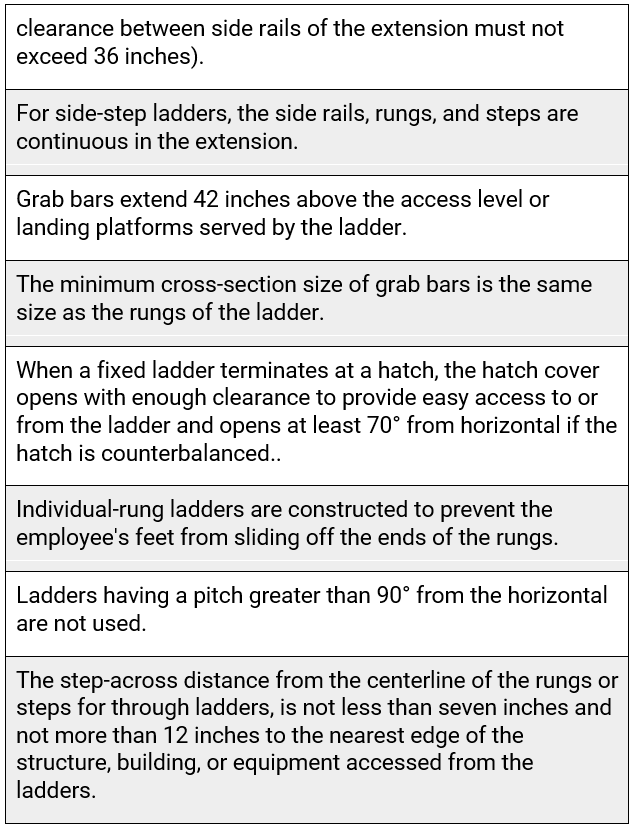

OSHA gets more granular with design requirements for specific types of fixed ladders above and beyond what’s specified under the General Requirements. Employers must ensure that:

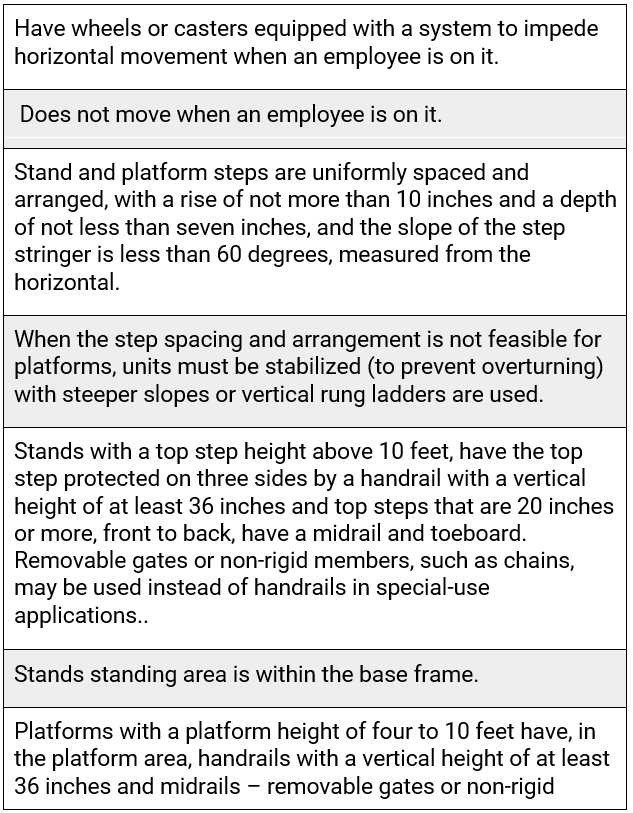

OSHA’s updated walking-working surfaces rule also addresses fixed ladders under 29 CFR 1910.28(b)(9), Duty to Have Fall Protection and Falling Object Protection. The rule phases in, over 20 years, a requirement to equip fixed ladders (that extend over 24 feet above a lower level) with ladder safety or personal fall arrest systems, and it prohibits the use of cages and wells as a means of fall protection after the phase-in deadlines. The rule grandfathers in cages and wells on existing ladders but requires that employers equip new ladders and replacement ladders/ladder sections with ladder safety or personal fall arrest systems during the phase-in period. Shown below are the established phase-in dates:

Mobile Ladder Stands and Mobile Ladder Stand Platforms

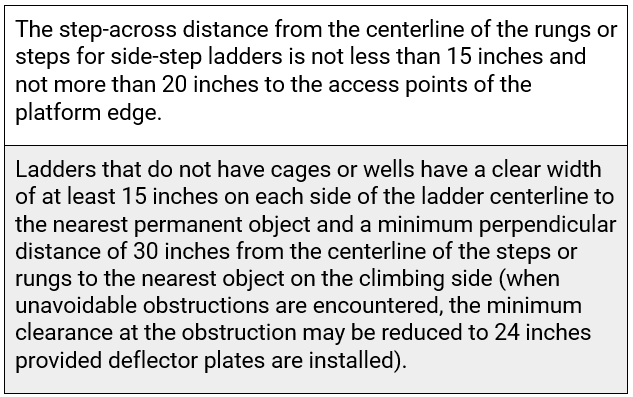

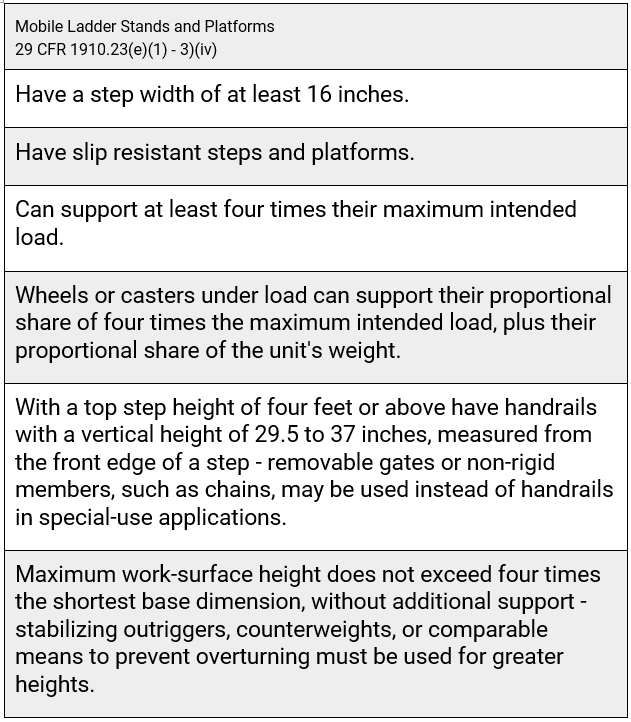

OSHA defines a mobile ladder stand as a mobile, fixed-height, self-supporting ladder that usually consists of wheels or casters on a rigid base and steps leading to a top step (29 CFR 1910.21(b)). A mobile ladder stand may also have handrails and is designed for use by one employee at a time. OSHA defines a mobile ladder stand platform as a mobile, fixed-height, self-supporting unit having one or more standing platforms that are provided with means of access or egress. Employers must ensure that:

ANSI-ASC Ladder Standards

ANSI – ASC consensus standards for ladders detail the materials, safe construction, design, testing, care and use, and labeling/marking for various types and styles of ladders, and include:

- ANSI-ASC A14.1-2017 – American National Standard for Ladders – Wood Safety Requirements

- ANSI-ASC A14.2-2017 American National Standard for Ladders – Portable Metal – Safety Requirements

- ANSI-ASC A14.3-2018 American National Standard for Ladders – Fixed – Safety Requirements

- ANSI-ASC A14.4-2018 American National Standard for Ladders Safety Requirements for Job-Made Wooden Ladders

- ANSI-ASC A14.5-2017 American National Standard for Ladders – Portable Reinforced Plastic – Safety Requirements

- ANSI-ASC A14.7-2011 American National Standard for Mobile Ladder Stands and Mobile Ladder Stand Platforms

- ANSI-ASC A14.8-2020 American National Standard Safety Requirements for Ladder Accessories

- ANSI-ASC A14.9-2019 American National Standard Safety Requirements for Disappearing Attic Stairways ANSI-ASC A14.11-2018 American National Standard Safety Requirements for Stepstools

Portable Ladder Styles and Types

Portable ladder styles include stepstools, stepladders, extension ladders, trestle ladders, combination ladders which may also be used separately as single ladders, mobile ladder stand ladders, and mobile ladder stand platform ladders,.

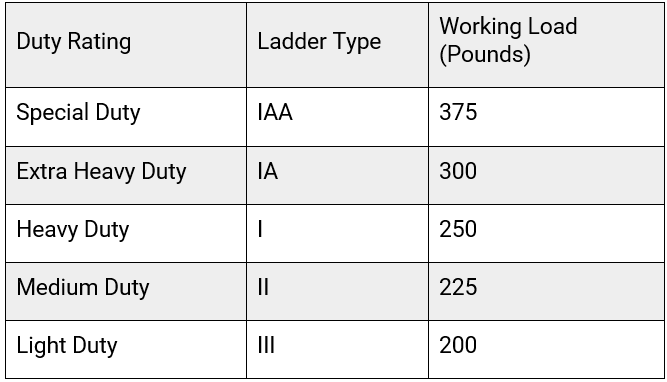

The duty rating of a ladder is an indication of the maximum weight capacity the ladder can safely carry. There is no relationship between ladder length and weight capacity. There are five categories of ladder duty ratings:

Portable Ladder Material Guidelines

The environment the finished ladder will encounter (electrical hazards, temperature extremes, corrosion, outdoor weathering, etc.) should determine the material.

ANSI-ASC recommends various species of wood that are suitable for ladders. Physical characteristics such as grain, knot, pitch, and compression must be controlled when constructing wood ladders.

Specific design and construction requirements for metal ladders are minimized because of the wide variety of materials and design possibilities. However, the designs must produce ladders of enough strength and stiffness to meet the performance requirements and must not have any structural defects or hazards such as sharp edges, burrs, etc.

Reinforced plastic ladders must use fully cured, commercial-grade, thermosetting polyester resin with glass-fiber reinforcement.

Test Requirements for Portable Ladders

Test requirements for the ladder materials vary. However, ladders generally are evaluated on their resistance to bending, strength in various positions, and the quality of the individual components that make up the ladder.

Portable Ladders Usage Guidelines

Usage guidelines for portable ladders encompass selecting the proper ladder for the job being performed; inspecting before use to verify proper operation and cleanliness; evaluating ladder placement so that footing and top supports are secure and not creating a traffic hazard for pedestrians; utilizing proper climbing technique; and caring for and storing ladders properly.

Before working with a ladder, read the manufacturer’s instructions. Do not use a ladder if sleepy or ill, if you are taking medication, or if there’s bad weather. Do not use ladders in doorways or other high-traffic areas. If a ladder must be used near a door, make sure the door is locked and it is marked with warning signs and/or cones. If the door must be open or the ladder is in a raised position, ask a coworker to stay with the ladder to make sure an incident does not occur. Use fiberglass or wood ladders, rather than metal, near power lines or other sources of electricity to avoid electrical shock hazards. Inspect your ladder for damage before using. During your inspection, if you find it is damaged remove the defective ladder from service and identify it with a “Do Not Use” tag.

Choose the right portable ladder for the job. When deciding which ladder to use – four key choices must be made:

- Choose the material – wood, metal (aluminum) or fiberglass – the environment of the work site dictates the material

- Choose the kind – several kinds for a variety of uses

- Select the proper length – it is unsafe to use a ladder that is too long or too short

- Consider the duty rating – indication of the maximum weight capacity the ladder can support

The Centers for Disease Control and Prevention / National Institute for Occupational Safety and Health (NIOSH) has developed a Ladder Safety App for mobile devices that features a multimodal indicator and a graphic-oriented guide for ladder selection, inspection, positioning, accessorizing and safe use. The app is available in English and Spanish and can be downloaded for both iOS and Android users.

Marking Requirements

Ladders must be marked with ladder size, type and/or duty rating, maximum working length (if extension ladder), highest standing level, total length of sections (if extension ladder), model number or name, manufacturer’s or distributor’s name, manufacturer’s plant location (if multiple plants may be coded), month and year of manufacture, and ANSI compliance and warranty (if applicable). Usage guidelines and other warning statements must also be placed on the ladders in specific locations depending on ladder type.

Sources

29 CFR 1910.21 Scope and definitions

29 CFR 1910.22 General requirements

29 CFR 1910.23, Ladders

29 CFR 1910.28, Duty to have fall protection and falling object protection

29 CFR 1910.29 Fall protection systems and falling object protection-criteria and practices

29 CFR 1910.145 Specifications for accident prevention signs and tags

ANSI-ASC A14.1-2017 – American National Standard for Ladders – Wood Safety Requirements

ANSI-ASC A14.2-2017 American National Standard for Ladders – Portable Metal – Safety Requirements

ANSI-ASC A14.3-2018 American National Standard for Ladders – Fixed – Safety Requirements

ANSI-ASC A14.4-2018 American National Standard for Ladders Safety Requirements for Job-Made Wooden Ladders

ANSI-ASC A14.5-2017 American National Standard for Ladders – Portable Reinforced Plastic – Safety Requirements

ANSI-ASC A14.7-2011 American National Standard for Mobile Ladder Stands and Mobile Ladder Stand Platforms

ANSI-ASC A14.8-2020 American National Standard Safety Requirements for Ladder Accessories

ANSI-ASC A14.9-2019 American National Standard Safety Requirements for Disappearing Attic Stairways ANSI-ASC A14.11-2018 American National Standard Safety Requirements for Stepstools

Centers for Disease Control and Prevention / NIOSH Ladder Safety

Commonly Asked Questions

Question: How should I handle objects safely while on a ladder?

Answer: According to the U.S. Bureau of Labor Statistics, 50% of all ladder related accidents were due to individuals carrying items as they climbed. Keeping tools in a tool belt will keep them handy and free up your hands for climbing. The use of accessories such as tool lanyards to keep tools tethered to the worker can prevent them from falling while working on a ladder. Any heavy or bulky items should be brought up only after you have reached the top. Signs or barricades can be used to warn others that work is proceeding above them, and that they should be aware of possible falling objects.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how