Infrared Thermometers – Quick Tips

Handheld infrared (IR) thermometers are used in many industries and work environments to measure surface temperatures rapidly and at a safe distance. Elevated temperature can be the first sign of trouble for mechanical equipment, electrical circuits and building systems. A quick temperature check of key components can find potential trouble areas and prevent catastrophic failures. This article will discuss the basics of infrared radiation, as well as two important concepts to understand when choosing and using an infrared thermometer: D:S ratio and emissivity.

Infrared Radiation and the Electromagnetic Spectrum

Infrared radiation is one type of radiation in the electromagnetic spectrum. Other types of electromagnetic radiation include microwaves, X-rays and visible light.

We can’t see infrared radiation—its wavelength is slightly too long for our eyes to perceive it as visible light—but we feel it on the skin as the sensation of warmth.

How is Infrared Radiation Used to Determine Temperature?

Like visible light, infrared energy can be focused, reflected and absorbed. Handheld IR thermometers use a lens to focus the infrared energy from an object onto a sensor that measures it, typically a thermopile. The sensor absorbs infrared radiation and converts it to an electrical signal, with more intense radiation creating a stronger signal. The IR thermometer processes this signal in order to deliver a temperature readout.

What Is Emissivity?

Everything emits infrared energy, but some things emit it more efficiently than others. Emissivity is a measure of this efficiency and the measurement is expressed in a range from 0 to 1. In general, surfaces that are reflective or shiny have lower emissivity than other surfaces. It’s important to understand emissivity, especially if you’ll be taking measurements from shiny or reflective surfaces. Failing to take it into account can result in incorrect temperature readings.

The simplest IR thermometers are designed to produce accurate measurements from surfaces that have an emissivity of approximately 0.95. According to test instrument manufacturer Fluke, most organic, oxidized or painted surfaces have emissivities close to that value. However, reflective surfaces have a much lower emissivity, which means that fixed-emissivity IR thermometers are not able to accurately measure their temperature directly. Polished aluminum, for example, has an emissivity of around 0.05.

One way to take more accurate temperature measurements from reflective surfaces is to use an IR thermometer that has variable emissivity settings. These can range from simple “high, medium and low” settings to fully adjustable settings. Check your device’s manual for the manufacturer’s recommended emissivity setting for specific materials.

Another way to take more accurate measurements from shiny surfaces is to add a piece of flat-black, non-reflective tape or a patch of high-temperature paint to the surface and take the reading from this non-shiny area, after it’s had time to come to temperature.

Selection tip: If you’ll frequently be measuring the temperature of shiny or reflective surfaces, you’ll probably want to consider an infrared thermometer that offers variable emissivity settings.

Using an Infrared Thermometer: Understanding Field of View and D:S Ratio

Because an IR thermometer uses an optical system with a lens to focus infrared energy, the area from which that energy is focused is sometimes called the thermometer’s field of view. The field of view is also sometimes called the spot. To get the best results from an infrared thermometer, you need to understand its field of view.

The field of view widens as the distance between the IR measuring device and the surface it’s measuring increases. The orientation of the device to the surface being measured also affects the field of view. To get the tightest field of view, hold the device at a perpendicular or 90° angle to the surface you’re measuring.

To use an IR thermometer correctly, it’s important to keep in mind that an IR thermometer measures the average temperature over its entire field of view. When a surface does not fill the instrument’s field of view, the instrument will be unable to measure its temperature well, because its readout will also include the temperature of things that are next to or behind the surface.

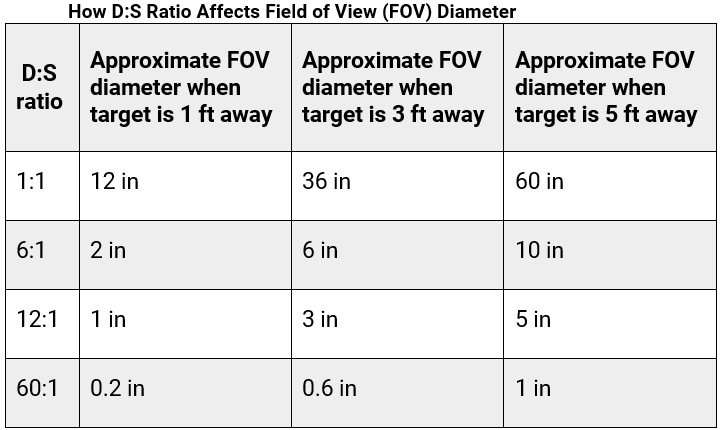

To determine the size of an IR thermometer’s field of view at a given distance, you can use the device’s distance-to-spot (D:S) ratio, also sometimes called distance-to-target ratio (DTR). The D:S ratio is related to the sophistication of the device’s optical system and can vary from 1:1 on inexpensive infrared thermometers to 60:1 or higher on high-end instruments.

This chart below shows examples of the field of view diameter for different D:S ratios at different measurement distances.

IR thermometers with high D:S ratios, such as 60:1, can measure smaller areas from a greater distance. Because the field of view of a device with a 1:1 D:S ratio expands so quickly as you get further away from the object, manufacturers typically recommend using them at as close distance as possible.

Selection tip: When choosing an IR thermometer, think about how far away you’ll need to be from the things you’re measuring, and how small those things are. The smaller and farther away the target, the higher D:S ratio you’ll need.

Laser Targeting System

Most IR thermometers have laser pointers to help target the measurement. The simplest of these targeting systems is a single laser that points at the approximate center of the field of view.

IR thermometers with more complex targeting systems use two or more lasers to indicate the full size of the field of view at the measured distance, which can save you the trouble of estimating its size on the fly using the D:S ratio. A dual-laser or multiple-laser instrument may be easier to use correctly, especially for an inexperienced operator.

Other Causes of Incorrect Readings

As described above, to get accurate measurements, the two most critical things to keep in mind are: field of view (D:S ratio) and emissivity. Nevertheless, there are a few other things that can potentially influence results:

- Steam, smoke, fog, frost and dust in the air can deflect some of an object’s infrared energy before it reaches the thermometer.

- A dirty or damaged lens on an IR thermometer can interfere with its ability to focus infrared radiation.

- An IR thermometer that has been stored somewhere that’s hotter or colder than the environment in which it’s being used may need some time to come to temperature before delivering accurate readings.

- Strong radio frequency (RF) interference can influence infrared temperature readings.

Temperature Range

IR thermometers have maximum temperature readouts that can be anywhere from a few hundred degrees to several thousand degrees Fahrenheit. Manufacturers usually describe the accuracy of the temperature measurements in both relative and absolute terms. For example, one thermometer might be accurate to within 3° F or 3%, whichever is greater. This means that at very high temperatures, the accuracy diminishes in absolute terms—but practically speaking, a difference of, say, 30° F is inconsequential when the measured temperature is 1000° F.

Selection tip: The three most important factors to consider when choosing an IR thermometer are temperature range, D:S ratio and emissivity functionality.

Clinical Non-contact Infrared Thermometers

Clinical non-contact infrared thermometers (also called medical non-contact thermometers) work on the same basic principles as industrial IR thermometers, but they have a specialized design that helps them produce accurate measurements of body temperature.

Clinical non-contact IR thermometers are considered medical devices and normally must be cleared for sale by the Food and Drug Administration (FDA). However, during the COVID-19 pandemic, the FDA temporarily relaxed this restriction to help prevent a shortage of these devices.

How Are Clinical Infrared Thermometers Different from Industrial Infrared Thermometers?

Here are some of the important differences between infrared thermometers designed to measure body temperature and industrial IR thermometers:

- Clinical non-contact IR thermometers are designed to produce highly accurate measurements over a very narrow range of temperatures (also known as “biological range”). In comparison, industrial IR thermometers are designed to produce slightly less accurate measurements over an enormous range of temperatures.

- Clinical non-contact IR thermometers are designed to be used only at close range, usually about two to six inches. Check the instruction manual for the correct distance for your specific device.

Additionally, clinical non-contact IR thermometers have a feature that compensates for the expected difference between skin temperature and internal body temperature. This compensation allows the clinical non-contact IR thermometer to produce a reading that’s more directly comparable to body temperature as measured by an under-the-tongue thermometer. Clinical non-contact IR thermometers are typically used for screenings, rather than for diagnostic measurements. In other words, a non-contact IR thermometer can identify people who may have a fever, but a readout from a complementary device, such as an under-the-tongue thermometer, would usually be required to diagnose that person with a fever.

Frequently Asked Questions

Q: Can infrared thermometers see through glass and plexiglass?

A: Glass, plexiglass and other visually transparent materials are usually “opaque” to infrared light. If you try to measure a temperature of something on the other side of a window, for example, the readout will tell you the temperature of the glass, even if the thermometer’s laser pointer passes through it.

Q: Can I use an industrial infrared thermometer to measure body temperature?

A: Most industrial IR thermometers are not well-suited to measuring body temperature. Many industrial IR thermometers produce measurements that are accurate to within three or four degrees Fahrenheit, which is acceptable for industrial applications but would not be helpful for determining whether or not a person has a fever. Also, the temperature of a person’s forehead is somewhat cooler than their internal body temperature, and clinical IR thermometers are designed to deliver readouts that compensate for this difference, while industrial IR thermometers are not. Check manufacturer’s specifications to determine whether an instrument can be used to measure body temperature.

Q: What’s the best way to clean an IR thermometer?

A: To be accurate, IR thermometers must be kept clean. To clean, use a soft cloth or cotton swab with water or medical grade rubbing alcohol and carefully wipe first the lens and then the body of the thermometer. Allow the lens to dry fully before using the thermometer. Never use soap or chemicals and never submerge any part of the thermometer in water. Industrial IR thermometers should be cleaned when dirty, or roughly every six months according to some manufacturers. Consult the instructions for your device before cleaning. Clinical IR thermometers used for temperature screening should be cleaned and disinfected according to manufacturer’s instructions and facility policies, according to the Centers for Disease Control and Prevention.

Q: How close do I need to be to an object to measure its temperature accurately with an IR thermometer?

A: There’s a quick way to estimate the maximum distance from which you can reliably measure an object of a certain size with an infrared thermometer: Multiply the size of the object by the first number in the distance-to-spot ratio.

For example, an IR thermometer with a D:S ratio of 12:1 can measure a 4-inch surface at a maximum distance of about 48 inches (12 x 4 = 48). This shortcut won’t work if the second number in the D:S ratio is anything other than 1, but instruments with such ratios are uncommon.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how