Hard Hat Requirements – Quick Tips

The Occupational Safety and Health Administration (OSHA) guidelines for head protection are referenced in 29 Code of Federal Regulations (CFR) 1910.135 and 1926.100.

Occupational Hard Hats

29 CFR 1910.135(a)(1) states, “Each affected employee shall wear protective helmets when working in areas where there is a potential for injury to the head from falling objects.” The standard also covers conditions where electrical hazards are present. 1910.135(a)(2) states, “Protective helmets designed to reduce electrical shock hazard shall be worn by each such affected employee when near exposed electrical conductors which could contact the head.” “Affected Employees” are defined by OSHA as “those employees who are exposed to the hazard(s) identified as violation(s) in a citation.” This definition has been added to clarify that the term, as used in this regulation, applies specifically to those employees who are put at risk by the safety or health hazard cited by the OSHA Compliance Officer.

Although the OSHA standards themselves do not identify specific occupations or applications where a hard hat is required, appendix B to subpart I part 9 lists some examples. It states “Some examples of occupations for which head protection should be routinely considered are: carpenters, electricians, lineman, mechanics and repairers, plumbers and pipe fitters, assemblers, packers, wrappers, sawyers, welders, laborers, freight handlers, timber cutting and logging, stock handlers, and warehouse laborers.” The appendix also provides examples of general applications where hard hats should be worn.

Performance Criteria

The performance criteria for head protection is provided in the American National Standards Institute (ANSI) Z89.1 American National Standard for Industrial Head Protection. This Standard is incorporated in 29CFR 1910.135 and by reference in 29CFR 1910.6.

Which Consensus Standards are applicable to Hard Hat Regulations?

On September 9, 2009, OSHA issued an update to its personal protective equipment (PPE) standards. The final rule went into effect in October that year and revised the PPE sections of OSHA’s general industry, shipyard employment, longshoring, and marine terminals standards regarding requirements for eye- and face-protective devices, head protection and foot protection.

The revision updated the references in these regulations to recognize the more recent editions of the applicable national consensus standards (ANSI/ISEA 789.1). It allows employers to use PPE constructed in accordance with any of three national consensus standards, the two most recent and the incorporated reference in the current standards (OSHA 1910.135).

In the future, OSHA plans on updating the national consensus standards referenced in the PPE standards as new editions become available.

ANSI Z89.1-1997

Beginning with the ANSI Z89.1-1997 standard, ANSI updated the classification system for protective helmets. Prior revisions used type classifications to distinguish between caps and full brimmed hats. Beginning in 1997, Type I designated helmets designed to reduce the force of impact resulting from a blow only to the top of the head, while Type II designated helmets designed to reduce the force of impact resulting from a blow to the top or sides of the head. To improve comprehension and usefulness, the 1997 revision also re-designated the electrical-protective classifications for helmets as follows:

- Class G (general) helmets: Designed to reduce the danger of contact with low-voltage conductors and are proof tested at 2,200 volts

- Class E (electrical) helmets: Designed to reduce the danger of contact with conductors at higher voltage levels and are proof tested at 20,000 volts

- Class C (conductive) helmets: Provide no protection against contact with electrical hazards

ANSI Z89.1-2003

ANSI published a revision to the Z89.1-1997 standard in 2003. The most significant changes from the 1997 version were made to harmonize with other national standards that test and evaluate equipment performance. In addition, many physical hard hat requirements that did not provide added user value, or that limited design or performance, were removed.

ANSI Z89.1-2009

ANSI published a revision in January of 2009. The significant changes from the 2003 version included three non-mandatory tests:

Reverse donning: Hard hats marked with a “reverse donning arrow” can be worn frontward or backward in accordance with the manufacturer’s wearing instructions. They pass all hard hat testing requirements, whether worn frontward or backward.

Lower temperature: Hard hats marked with an “LT” indicate that the hard hat meets all testing requirements of the standard when preconditioned at a temperature of -30°C (-22°F).

High visibility: Hard hats marked with an “HV” indicate that the hard hat meets all testing requirements of the standard for high visibility colors. This includes tests for chromaticity and luminescence.

ANSI/ISEA Z89.1-2014

There were three main changes to the ANSI/ISEA Z89.1-2014 standard issued on May 15, 2014:

- Under the section of Accessories and Replacement Componentsthere is further clarification that accessory or component manufacturers are required to prove that their components do not cause the helmets to fail. Helmet accessory or component suppliers must provide justification upon request that their product would not cause the helmet to fail the requirements of the Head Protection Standard.

- Some additional language added under the Instructionsand Markings section to help clarify that “useful service life” for helmets is not required by the Standard. It is up to helmet manufacturers if they want to include specific service life in terms of years. Manufacturers could elect to specify the number of years for their helmet’s service life or elect to identify certain conditions that may affect a helmet’s protection capability over time.

- The last section revised was the Higher Temperature section for users who work in hot environments. This section was updated to incorporate an optional preconditioning at a higher temperature of 140º F +- 3.6º F (60º C +- 2º C). Previously hot temperature preconditioning was conducted at 120º F +- 3.6º F (48.8º C +- 2º C) under the 2009 Standard. Helmets that meet the performance criteria after being preconditioned to these higher temperatures (140º F) will be designated with a HT marking.

Markings

According to the ANSI/ISEA standard, hard hats must also contain user information such as instructions pertaining to sizing, care and service life guidelines. Every hard hat conforming to the requirements of ANSI Z89.1-2014 must be appropriately marked to verify its compliance. The following information must be marked inside the hard hat:

- The manufacturer’s name or identifying mark

- Date of Manufacture

- The legend, “ANSI Z89.1-2014”

- The Type and Class Designation

- The approximate head size range

If optional performance features are applicable, the appropriate marking(s) below must be applied in the sequence as shown:

– Reverse Donning

– Reverse Donning- LT – Lower Temperature

- HV – High Visibility

- HT – Higher Temperature

Service Life

One common misconception is that hard hats have a predetermined service life – that is not the case. All hard hat components and accessories should be inspected daily for signs of dents, cracks, penetration and any damage due to impact, rough treatment or wear that might reduce the degree of protection originally provided.

In addition to everyday wear and tear, ultraviolet (UV) radiation can pose a problem for hard hats constructed of plastic materials. Damage caused by UV radiation is easy to spot: the hat will lose its glossy finish and eventually take on a chalky appearance. Further degradation could cause the shell to actually start flaking away. A helmet with worn, damaged or defective parts should be removed from service.

Useful service life guidelines supplied by the helmet manufacturers are intended to provide the user with information that certain conditions may affect a specific helmet’s continued protection over time. Specific service life, defined in terms of number of years, is not required though individual manufacturers may choose to include such information for their helmets.

Commonly Asked Questions

Q: Can I paint or put decals on my hard hat?

A: OSHA would consider painting or placing adhesive stickers acceptable if the manufacturer authorizes the alteration or the employer can demonstrate the reliability of the helmet is not affected by the paint or the adhesive on the stickers, and if the paint or placement of stickers would not reduce the ability to identify defects (i.e., use of see-through stickers) or other conditions that would indicate a reduced reliability.

Q: Does the ANSI Z89.1 standard cover bump caps?

A: The American National Standard for Industrial Head Protection (Z89.1) does not cover bump caps, firefighting helmets or head protection devices used in recreational activities.

Q: Can a cap, scarf, liner or other items for purposes of cold weather protection be worn safely with a hard hat?

A: OSHA recommends that employers permit only liners that are specifically designed to be compatible with the protective properties of the hard hat. They also recommend that the employer contact the hard hat manufacturer to determine if any type of liner or garment is compatible with the use of the hard hat. Further information can be found in OSHA’s standard interpretations Letter dated April 17, 2006.

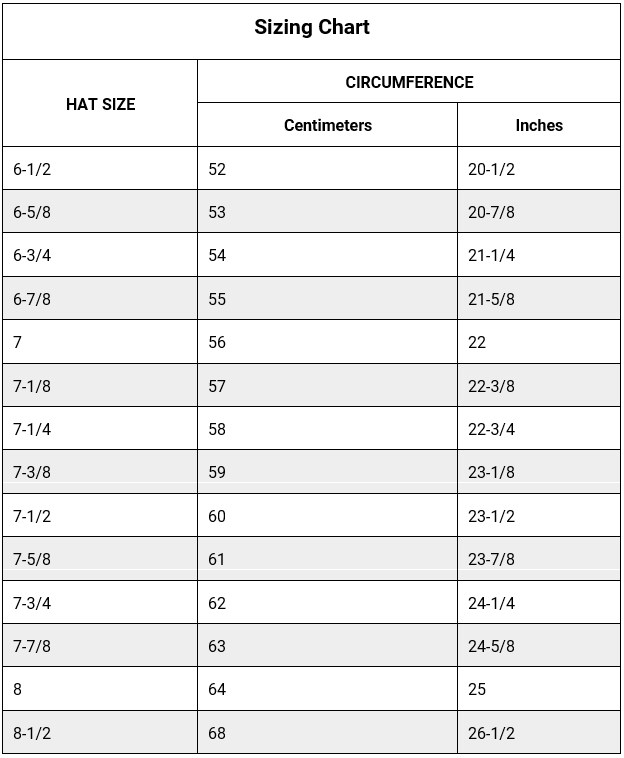

Q: How can I tell what size hard hat to wear?

A: Here is a simple chart that converts the circumference of your head into hard hat sizing.

Note: This table is intended for sizing guidance of round head bands only and should not be construed as prohibiting larger or smaller headbands.

Sources

Quick Tips #192: Hazard Assessment Form

Occupational Head Protection Standard

1910 Subpart I App B,

American National Standard for Industrial Head Protection

ANSI/ISEA Z89.1-2014

Non-mandatory Compliance Guidelines for Hazard Assessment and Personal Protective Equipment Selection.

ANSI Z89.1-2009

American National Standard for Personal Protection—Protective Headwear for Industrial Workers

ANSI Z89.1-2003

American National Standard for Personal Protection—Protective Headwear for Industrial Workers

ANSI Z89.1-1997

American National Standard for Personal Protection Protective Headwear for Industrial Workers

OSHA’s Standard Interpretations Letter dated April 17, 2006.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.