Globally Harmonized System GHS – Quick Tips

The revised Hazard Communication Standard has changed the way we identify, label and protect ourselves from hazardous chemicals.

The much-anticipated revision to the Occupational Safety and Health Administration’s (OSHA’s) Hazard Communication Standard (29 Code of Federal Regulations [CFR] 1910.1200) was published in the Federal Register on March 26, 2012 and was effective 60 days thereafter. One of the most significant changes in this revision was OSHA’s adoption of portions of the Third Edition of the United Nations’ Globally Harmonized System of Classification and Labeling of Chemicals (GHS).

History

Since 1985, the Hazard Communication Standard has been the primary tool for providing employers and employees with information about the chemical hazards in their workplaces. Until the 2012 revision the performance-oriented standard allowed chemical manufacturers and importers to convey information on labels and material safety data sheets (MSDSs) in whatever format they desired. While the information has been helpful, a more standardized approach to classifying the hazards and conveying the information was needed.

Born out of the United Nations’ Earth Summit of 1992, GHS is an international approach to the classification of hazardous chemicals and the communication of hazards to workers via labels and safety data sheets. It is not a law; rather it is a system with components that countries can adopt into their own systems. GHS affects everyone in the chemical lifecycle, with special responsibilities for chemical manufacturers and employers that handle, use and store hazardous materials.

Major Changes

The revised Standard addresses three major areas of change – hazard classification, shipped container labels and safety data sheets (SDSs).

The definitions of hazard changed to provide specific criteria for classification of health and physical hazards and for the classification of mixtures. These help ensure that evaluations of hazardous effects are consistent across the board and shipped container labels and SDSs are therefore more accurate.

Chemical manufacturers and importers must provide a harmonized shipped container label that has six standardized elements for classified hazards:

- Product identifier — Must match product identifier on SDS

- Manufacturer, importer or other responsible party contact information — Including name, phone number and address

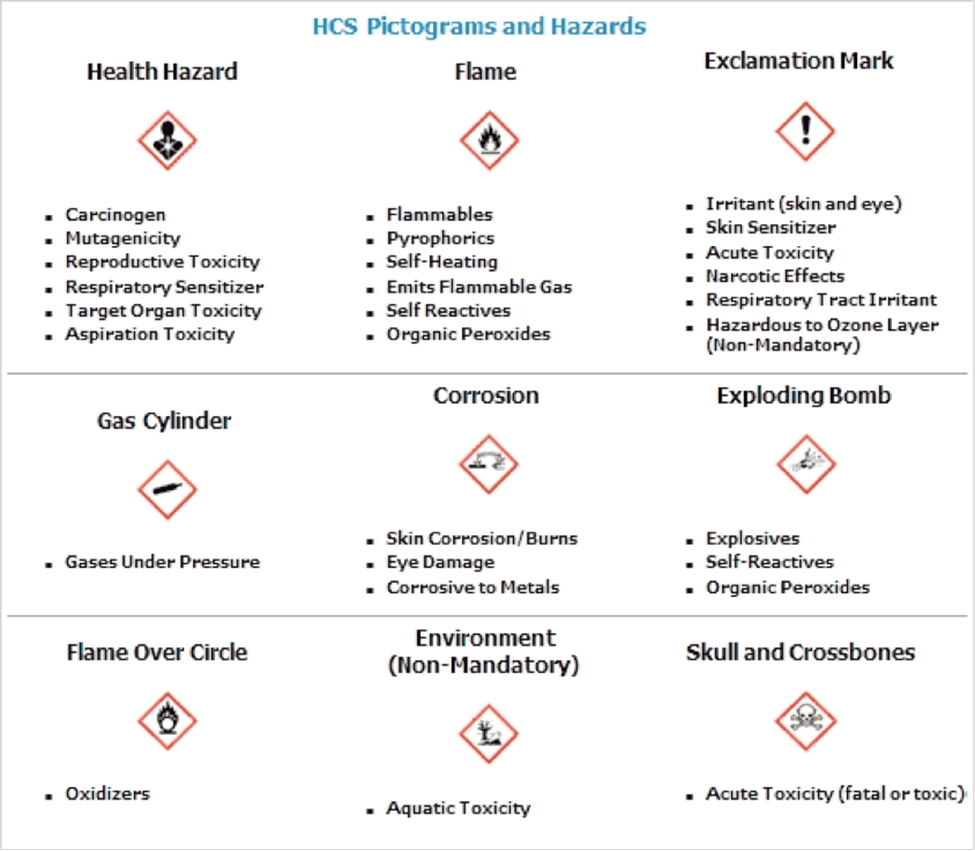

- Hazard pictograms — There are nine pictograms used to convey the health, physical and environmental hazards, but OSHA only addresses eight. The environmental pictogram is the exception, as environmental hazards are not within OSHA’s jurisdiction. These pictograms have a black symbol on a white background with a red diamond frame (see illustrations below):

- Signal word — either DANGER or WARNING depending upon hazard severity

- Hazard statements — Standardized sentences that describe the level of the hazards

- Precautionary statements — Steps employees can take to protect themselves

The signal word, hazard statement(s) and pictogram(s) must be located together on the label [29 CFR 1910.1200(f)(3)].

With the revision, OSHA continued to give employers the flexibility to determine what types of workplace labels they use. Employers have the ability to choose to label workplace containers either with the same label information that the chemical manufacturer, importer or other responsible party uses on the shipped containers or with alternate labels that meet the requirements of the standard.

SDSs remain the backbone of the Hazard Communication Standard. With the revision, there was a name and formatting change. The “M” was dropped from MSDS, and more importantly, a standardized 16-section format with a required ordering of sections became mandatory. The sections, in order, are:

- Identification

- Hazard(s) Identification

- Composition/Ingredient Information

- First Aid Measures

- Fire-Fighting Measures

- Accidental Release Measures

- Handling and Storage

- Exposure Control/Personal Protection

- Physical and Chemical Properties

- Stability and Reactivity

- Toxicological Information

- Ecological Information

- Disposal Considerations

- Transport Information

- Regulatory Information

- Other Information

To be compliant, all 16 sections of a SDS are required. However, OSHA does not enforce sections 12 to 15 because they fall outside the agency’s jurisdiction.

Effective Dates

Employers were required to train their workers on the new shipped container label elements and SDS format by December 1, 2013.

Chemical manufacturers, importers, distributors, and employers were required to comply with all modified provisions of the final rule by June 1, 2015. However, distributors could ship products labeled by manufacturers under the old Standard until December 1, 2015. On February 9, 2015, OSHA issued an internal memorandum directed at chemical mixture manufacturers and importers only. Extensions of up to six months were given on an inspection-by-inspection basis to those who exercised reasonable diligence and good faith to obtain the required classification and SDS information from their raw material suppliers. In these limited situations, distributors were allowed to ship chemicals labeled with old Standard compliant labels until December 1, 2017.

By June 1, 2016, employers were required to update their alternative workplace labeling and hazard communication programs as necessary and provide additional worker training for new identified physical and health hazards.

Summary

When the Hazard Communication Standard first took effect in 1985, employees got the right to know what their potential exposure to hazards might be. With this revision, employees not only know about the potential hazards, they also have a better understanding of what the warnings mean, what to do if exposed and how to protect themselves.

Commonly Asked Questions

- How often is the UN GHS updated?

A:The UN GHS is updated every two years. The 2012 revision to the Hazard Communication Standard was based on the Third Edition of the GHS which was published in July, 2009.

Q: I do not produce or import chemicals I only use them — what portions of the Hazard Communication Standard must I focus on?

A: Employers that do not produce or import chemicals need only focus on those parts of the Standard that deal with establishing a workplace program and communicating information to their workers.

Sources

OSHA Website — Hazard Communication Harmonized System of Classification and Labeling of Chemicals (GHS) Third Edition —The Purple Book Hazard Communication Directive CPL 02-02-079

(Rev 7/2018)

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how