Comparative Noise and Light Levels – Quick Tips

The potential for dangerous noise levels and harmful light levels exists in many day-to-day personal and workplace activities. The following information provides a better understanding of the comparative noise and light levels to a number of locations and applications.

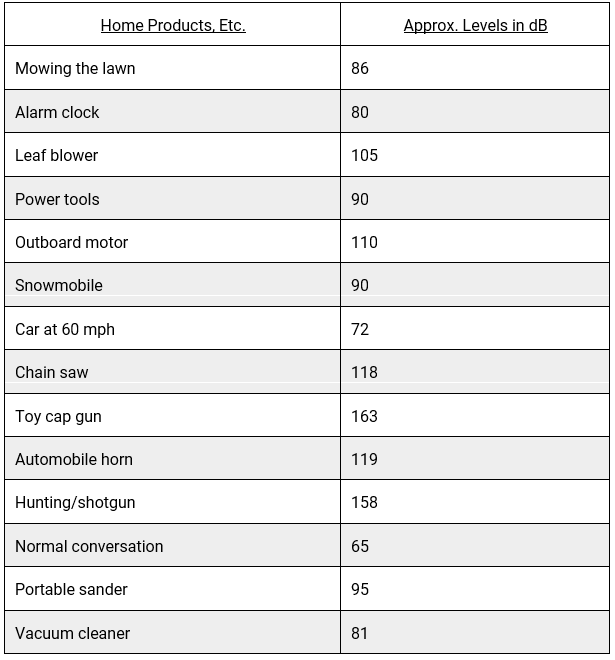

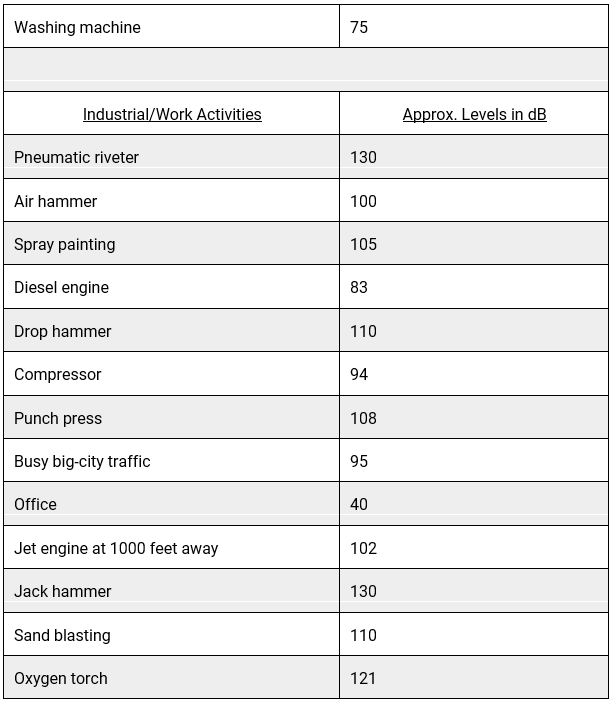

Noise Levels

Hearing loss (recordable or reportable) is addressed under OSHA in 29 CFR 1904. According to the OSHA regulation, hearing protectors must be made available to workers exposed at or above the action level of 85 dB. OSHA requires that hearing protectors be provided and worn by employees when:

- Noise exposures exceed 90 dB

- Employees are exposed to greater than 85 dB and have not yet had a baseline audiogram or have experienced a standard threshold shift (loss of hearing)

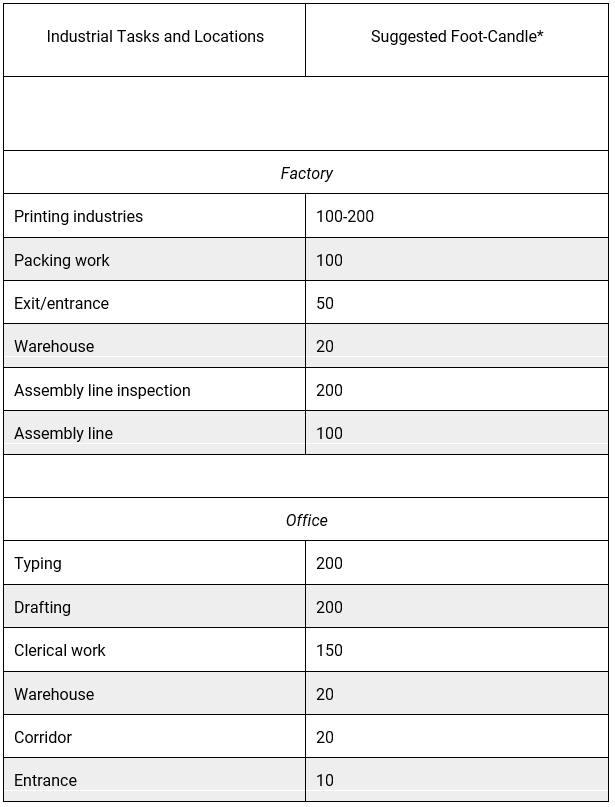

Light Levels

* Illumination levels are suggested and intended to be a minimum on the task referenced. To assure these values at all times, higher initial levels should be provided as required per task.

Commonly Asked Questions

Q: What are three indicators that I might be exposed to too much noise?

A: Three indicators of excessive noise exposure:

- Difficulty understanding normal conversation at work with someone two feet away.

- Prolonged ringing in the ears or other unusual noises after leaving work.

- Trouble hearing TV or speech, but can hear normally again after a few hours once off the job.

Q: When can a person begin experiencing hearing pain?

A: Depending on an individual’s hearing sensitivity, a person can begin experiencing hearing pain between 125 and 160 dB.

Q: When does OSHA require employers to implement a hearing conservation program?

A: In the United States, whenever employee noise exposures equal or exceed an eight-hour time-weighted average sound level of 85 dB. For more information, see Quick Tips #260: Effective Hearing Conservation Program Elements.

Q: What are three forms of hearing protection?

A: Earplugs, earmuffs and hearing bands.

Sources

Pattys Industrial Hygiene & Toxicology, Third Revised Edition, 1978.

Safety Technicians Handbook, Webber Publishing, 1996.

Lab Safety Supply Insights, May 1992 Volume 1, Issue 1.

Plant Engineering, July 18, 1991.

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how