Alternative Workplace Labeling – Quick Tips

The Occupational Safety and Health Administration’s (OSHA’s) Hazard Communication Standard found in 29 Code of Federal Regulations (CFR) 1910.1200 was promulgated on November 25, 1983 and became effective two years later. Since that time, the performance-orientated Hazard Communication Standard has been the primary tool for providing employers and employees with information about the chemical hazards in their workplaces

A much-anticipated revision to the Standard was published in the Federal Register on March 26, 2012 and became effective 60 days thereafter on May 25, 2012. One of the most significant changes in this revision was OSHA’s adoption of portions of the United Nations’ Globally Harmonized System of Classification and Labeling of Chemicals (GHS) Third Edition. There were three major areas of change – hazard classification, shipped container labels and safety data sheets (SDSs).

However, the parts of the Standard not related to the GHS—basic framework, scope and purpose—remained largely unchanged. The Hazard Communication Standard now requires chemical manufacturers, importers and distributors to provide a shipped container label that has six standardized elements:

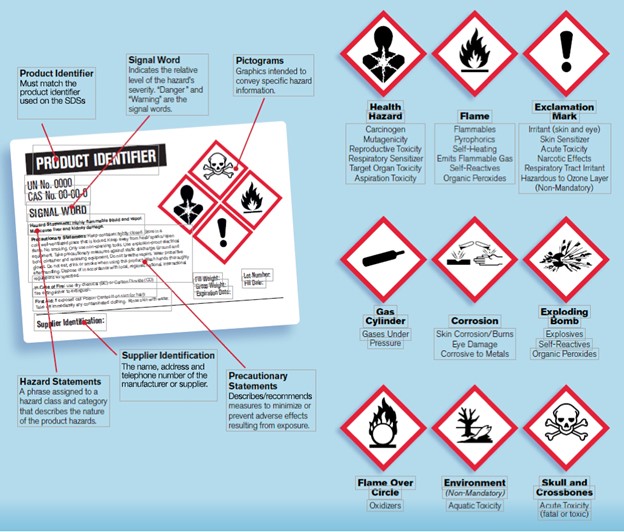

The Hazard Communication Standard now requires chemical manufacturers, importers and distributors to provide a shipped container label that has six standardized elements:

- Product Identifier – Must match product identifier on SDS.

- Manufacturer/Supplier Contact Information – Including name, phone number and address.

- Hazard Pictograms – There are nine pictograms used to convey health, physical and environmental hazards. OSHA requires eight of these pictograms, the exception being the environmental pictogram as environmental hazards are not within OSHA’s jurisdiction. These pictograms have a black symbol on a white background with a red diamond frame (see illustrations below).

- Signal Word – Either DANGER or WARNING depending upon hazard severity.

- Hazard Statements – Standardized sentences that describe the level of the hazards.

- Precautionary Statements – Steps employees can take to help protect themselves.

With the revision, OSHA continues to allow employers the flexibility to determine what types of workplace labels they will use. Two options are available:

- A label with the same information listed on the shipped container label.

- An alternate label that meets the requirements of the revised Standard.

There are several alternate workplace labeling systems:

- Right-to-Know (RTK)

- National Fire Protection Association (NFPA)/National Fire Rating (NFR) – 704

- Hazardous Material Identification Guide (HMIG)

- Hazardous Material Identification System (HMIS)

Alternate Workplace Labeling

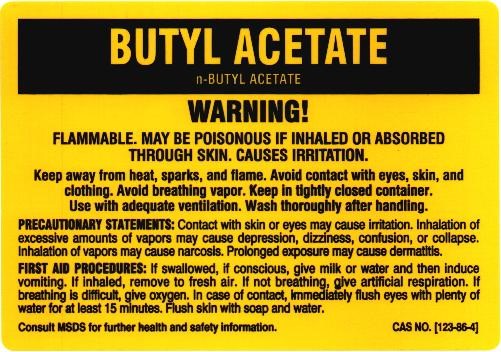

RTK

Consists of labels that list the chemical name, synonym or common name, hazard information, Chemical Abstract Service (CAS) number, precautionary measures and first aid procedures.

NFPA/NFR 704

The NFPA/NFR labeling systems employ a color-coded rating guide in a diamond shape. Health is defined by the color blue, flammability is red and instability is represented in yellow. The numbers 0–4 are assigned according to the level of hazard the chemical(s) present (0 being no hazard and 4 the greatest hazard). The hazards are arranged spatially as follows: health at the nine o’clock position, flammability at the twelve o’clock position and instability at the three o’clock position. The six o’clock position on the symbol represents special hazards and has a white background. The special hazards in use include unusual reactivity with water (W), the material is an oxidizer (OX) or the material is a simple asphyxiant gas (SA). This labeling option offers books, charts and wallet cards to help explain the classification.

NFR signs are commonly seen on the exterior of a building or on a storage vessel containing a hazardous chemical. In the event of a fire or emergency these signs alert the fire department or emergency responders to the types of chemical hazards that are present.

HMIG

Presents a color formatted label and is rectangular in shape. The numbers used in this system to identify the hazard level of the chemical are based on the acute and chronic hazards present in normal day-to-day use in the workplace and range from 0 (no hazard) to 4 (greatest hazard). There are also charts, labels and wallet cards for this system.

The numbers for the HMIG labeling systems may be obtained by reviewing the Safety Data Sheets (SDSs) accompanying the chemical or in reference books that list chemical hazards by the numerical rating, such as The Fire Protection Guide to Hazardous Materials. These three labeling systems (RTK, NFR and HMIG) are all offered through Grainger.

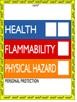

HMIS III

This label system looks similar to the HMIG labeling system (using the color bar format and rectangular shape) and utilizes a rating system developed by the National Paint and Coatings Association. The four bars are blue for health, red for flammability, orange for physical hazard and white for personal protection. The number ratings range from 0 – 4. The health bar has two spaces, one for an asterisk and one for the numeric hazard rating. If present, the asterisk signifies a chronic health hazard, meaning that long-term exposure to the material could cause a health problem.

Any of these alternate workplace labeling methods may be used as long as the employee understands the hazards being communicated and how to read the label. However, once a system has been chosen, OSHA prefers to see consistency throughout the workplace.

Commonly Asked Questions

Q: Is one of the chemical labeling systems better than another?

A: No. One labeling system is not better than the other. However, keep in mind consistency is the key. Once you choose a system, all chemicals should be labeled the same.

Q: When must the NFPA 704 rating system be used?

A: The NFPA / NFR 704 rating system is required when another Federal, state or local regulation or code or an authority having jurisdiction (AHJ) requires its use. Some of the more widely adopted and used NFPA codes that require 704 for specific occupancies, storage, and hazardous materials include NFPA 1, Fire Code, NFPA 30, Flammable and Combustible Liquids Code and NFPA 400, Hazardous Materials Code.

Sources

OSHA’s 29 CFR 1910.1200 Hazard Communication Standard

OSHA Label and Pictogram Technical Brief, February 2013

The Fire Protection Guide to Hazardous Material

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how