Air Monitor Sensor Selection – Quick Tips

Air monitors may be one of the most important pieces of life-saving equipment in your company’s inventory; unfortunately, they are also sometimes the most neglected. This document is intended to be a guide to understanding how the sensor technology works in most portable gas monitors and what you can do to ensure that your air monitor is working properly. You should always follow specific manufacturer’s instructions for care and use of your air monitors.

Background

Air monitors are offered as either single-gas or multi-gas monitors/detectors. Single-gas air monitors have one sensor for detecting an individual gas and multi-gas monitors are available with many possible combinations of different sensors to detect many different gases like oxygen, chlorine, carbon monoxide, hydrogen sulfide, ammonia, methane and many others. This document focuses on the technology utilized for the most common sensors used in air monitors: oxygen, combustible gas (LEL sensor), and toxic sensors.

Sensor Technologies

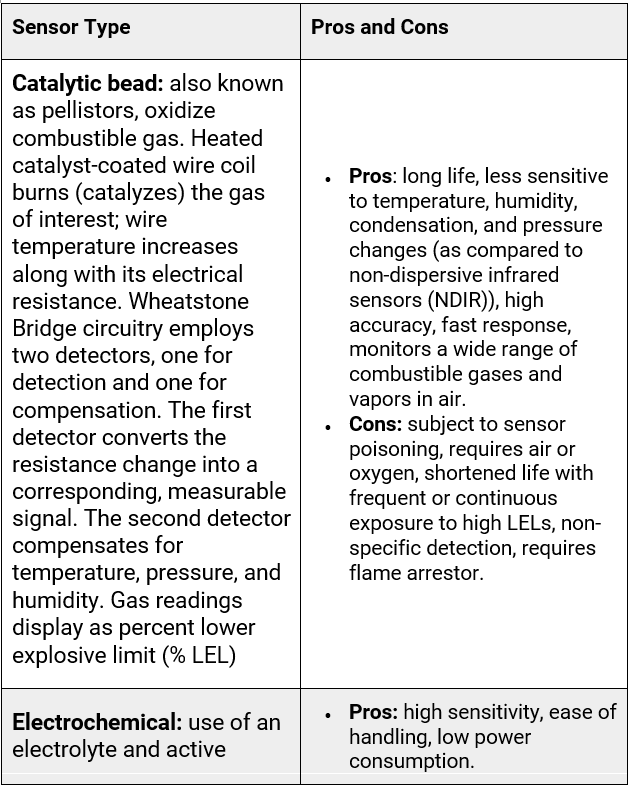

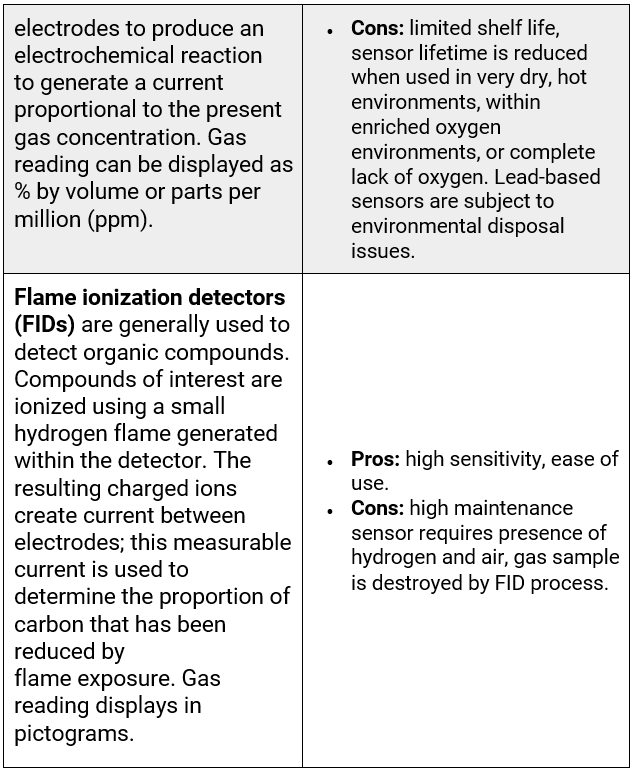

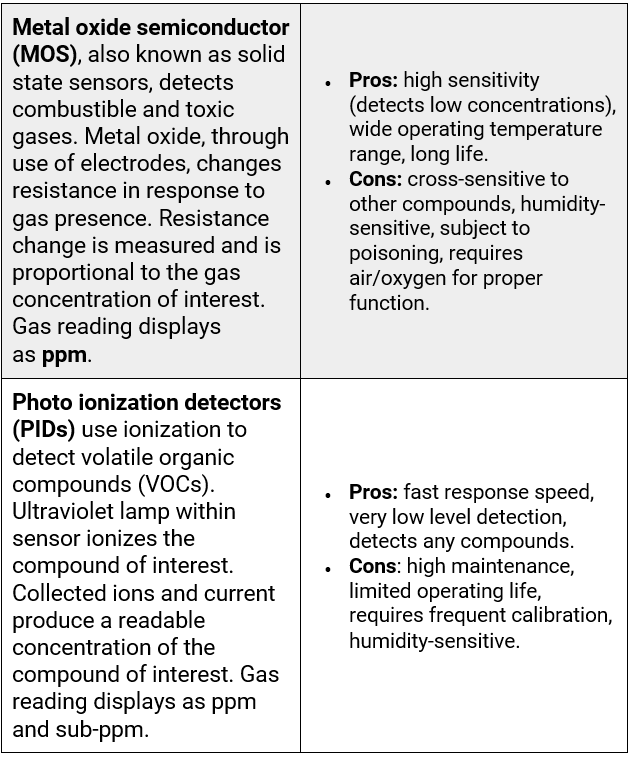

There are many sensor technologies utilized in air monitors and each offers pros and cons. The most utilized in the market are:

Source: Industrial Safety Equipment Association (ISEA)

Oxygen sensors: Use electrochemical sensors. These are considered a consumable sensor, meaning that something inside the sensor is used up when exposed to oxygen. For example, some oxygen sensors use lead. When the reaction takes place, the lead is converted to lead oxide. Eventually, the sensor consumes all the lead inside, and the sensor will fail and must be replaced. An oxygen sensor is always working in a gas detector circuit—even if your monitor is turned off. Anytime the oxygen sensor is stored in air, your sensor life is steadily decreasing. Some manufacturers suggest temporarily removing the sensor from the unit or storing the unit in an airtight container. These suggestions will only slightly extend the life of the sensor, and if you remove a sensor, there can be a 15-minute to four-hour or more warm-up period required before you can use the sensor again. Oxygen sensors are usually warranted for one or two years, but a typical oxygen sensor should last around two years.

Toxic sensors: Typically use electrochemical and MOS sensors. These are nonconsumptive; meaning nothing is consumed when it is exposed to the target agent. Theoretically, a toxic sensor should last indefinitely, but factors such as leakage and contamination limit the life of these sensors. Most manufactures warranty their toxic sensors for two years. However, they can last up to four or more years. Toxic sensors contain an acid electrolyte that can damage your instrument if they leak. Waiting to replace an old sensor can lead to costly repairs.

Combustible (LEL) sensors: Use catalytic bead sensors, PIDs, and FIDs Combustible sensors are different from the other sensors as they are a solid-state catalytic bead sensors, not a wet electrochemical. PIDs and FIDs are used to identify specific combustibles to a much lower range (typically < 100 ppm) versus a % LEL sensor (1%=10,000ppm).(Most LEL sensors are guaranteed one or two years, but they can last up to four or more years. Many factors can shorten the life of an LEL sensor. A strong shock, such as dropping an instrument, could break the fine wire inside the sensor resulting in an immediate failure of the sensor. If an LEL sensor encounters a fuel-rich but oxygen-deficient environment, tars, carbon and unburned fuel can build up on the active bead, which can lead to sensor failure.

Certain types of materials will also poison the combustible sensor, rendering it ineffective. These poisons include tetra-ethyl lead (found in leaded gasoline), volatile silicone oils, room temperature vulcanizing (RTV) silicone products, halogenated hydrocarbons (freon, methylene chloride, etc.) and very high concentrations of hydrogen sulfide or other sulfur-containing gases. When a combustible sensor becomes poisoned, the first gas that it loses sensitivity to is methane. This means that a poisoned sensor may exhibit a loss of sensitivity when exposed to methane but can respond normally to other combustible gases. This is particularly important if you are calibrating with pentane or another calibration gas other than methane. Many manufacturers are making equivalent gases that are methane-based to test sensors for poisoning while still allowing a sensor to be calibrated to a different sensitivity scale than methane.

Conclusion

There is a risk of injury, illness or even death from oxygen deficiency or toxic/combustible gases in many work environments. Using a proper air monitor and understanding the sensor detection technology behind it is a must..

Commonly Asked Questions

Q: If I calibrate my LEL sensor with methane, will it still detect pentane?

A: A typical LEL sensor is nonspecific and will respond to all combustible gases. The problem is that the amount of heat produced on the active bead in the LEL sensor is different for different combustible gases. If the gas you are detecting is different from the gas you used for calibration, your monitor will give % LEL readings on the display based on your calibration gas. These readings may be higher or lower than actual. In the case of pentane, your display will be lower than the actual levels because the sensor was calibrated with methane. Manufacturers provide LEL correlation factors with their units, so you can calculate the LEL of the sampled gas based on your calibration gas. If you can, it is always best to calibrate your monitor with the gas that you expect to find. If you cannot calibrate to the specific gas, calibrate your instrument with a gas that responds the closest to it and make sure that you have the alarm set at 10% LEL or less. At 10% LEL or below, the differences due to sensor response are minimal.

Q: Are there temperature limitations for air monitors?

A: Yes, there are temperature limitations for air monitors. At high or low temperatures, sensors will not respond correctly and displays and batteries can fail. Operating temperatures vary by instrument. Always follow the manufacturer’s operating temperature guidelines.

Sources

The information contained in this article is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This article is not a substitute for review of current applicable government regulations, industry standards, or other standards specific to your business and/or activities and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Source: Grainger Know How – https://www.grainger.com/know-how